Technical characteristics and rules of use of primer-enamel XB-0278

A primer helps increase the life of the metal. These formulations prevent the formation of rust. But usually these products are used first, then the paint is applied, which increases the duration of the work. The solution to this problem will be the use of XB-0278 primer-enamel, which both colors and protects the metal from corrosion.

Description and characteristics of the composition

Primer-enamel is a universal product intended for painting metal surfaces, including those covered with a layer of rust. The basis of the product consists of perchlorovinyl, alkyd and epoxy resins. The product also contains corrosion inhibitors, rust converter, pigments and plasticizers.

This enamel can be used as an independent coating, which is applied in three layers:

- The first acts as a rust converter, which stops and prevents the development of corrosion.

- The second performs the role of a primer, which not only provides corrosion protection, but also increases the adhesion properties of the metal.

- The third acts as a decorative coating, which also protects the material from external influences.

It is forbidden to use XB-0278 for processing non-ferrous metals. In addition, this primer protects the bodywork well from corrosion.

Primer enamel is recommended for surface treatment with a layer of rust up to 70 micrometers thick. In this case, the material requires the application of an additional layer of paint. The coating obtained after metal transformation has the following characteristics:

- elastic;

- strong and durable;

- resistant to the effects of aggressive gases and solutions (therefore, suitable for use in industrial facilities);

- tolerates contact with salt solutions heated to a temperature of not more than +6 degrees;

- protective properties under moderate conditions are maintained for four years.

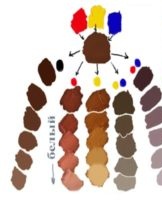

This enamel can have any color. Popular shades are yellow, white, brown, black and gray. But if necessary, at the request of customers, other colors can be mixed in production by adding appropriate pigments to the original resins.

Primer Specifications

Primer XB-0278 is produced in accordance with GOST 6617. This product is accompanied by an official certificate, which indicates the technical characteristics of the enamel:

- viscosity index (measured at room temperature) - 30 s for black enamel and 40 s for other types;

- the volume of non-volatile components - 34-44% for black primer and 30-36% for other colors;

- drying time - one hour at a temperature of 22-24 degrees;

- layer thickness - 20-25 micrometers (first layer) and 20-40 micrometers (next);

- grinding rate - no more than 40 micrometers;

- the recommended number of coats is 2-3;

- elasticity of the dried layer for bending - up to one millimeter;

- rust conversion coefficient - from 0.7;

- the level of adhesion is 1-2 points.

According to the measurements carried out, the dried enamel is able to withstand the effect of a 3% solution of potassium chloride at room temperature for three days. The finished coating has a hardness index greater than 0.15. After processing, a dense homogeneous layer with a matte shine is formed on the surface of the metal.

Apps

You can use XB-0278 enamel primer to paint:

- various metal structures, both at home and in industrial facilities;

- machines and installations which are constantly in contact with aggressive substances and vapours, water, reagents;

- metal covered with a layer of rust;

- cast iron, steel and iron, including areas where there are traces of scale or carbon deposits;

- large metal structures, including complex shapes;

- car parts.

Also, this primer is used to prepare the base, on which a refractory layer is then applied. If necessary, enamel is used for painting reinforced concrete structures, including fences, walls and curbs.

Preparing for the application

It is recommended to remove loose rust from the surface before applying the enamel coat. You must also remove the remains of paint and varnish present on the metal.

When performing the work, the following recommendations should be taken into account:

- use the dry spray method only if properly trained;

- use the solvents suitable for the primary enamel (the list is indicated in the instructions);

- do not use the painted product before the end of the primer drying period;

- apply the enamel to a rough surface (otherwise the primer will not be absorbed).

In addition, it is recommended to clean the surface from dust, dirt and traces of grease. If it is necessary to paint smooth metal, the material is pre-treated with fine abrasive emery paper.This will help increase adhesion. It is also not recommended to apply less than one coat of product. In this case, after processing, only rust deposits will be removed. With corrosion, the primer will also fade. That is, the product will be unpainted and unprotected against the appearance of rust.

Work execution

Before starting to paint, the enamel primer must be mixed with R-4 or R-4A solvent. Also, compositions P-670 and P-670A are suitable for this tool. It is impossible to mix the primer-enamel with other solvents. This is due to the fact that the product prepared in this way will dry longer. And it is forbidden to use white spirit with this primer.

The proportions of solvent and enamel dilution are not indicated by the manufacturer. The viscosity is determined according to the mode of application of the product (roller or brush require a more viscous product than in spraying). You need to add the solvent in a large volume, constantly mixing with the primer.

This product applies the same way as any other paint. For small areas, you can use a brush or a roller. When painting large objects, it is recommended to use a spray gun or a spray gun. In some cases, the enamel is applied by dipping the items in the prepared mixture. But this option is suitable for small structures.

It is recommended to process metal surfaces at temperatures from -10 to +30 degrees. The humidity level should be 55 to 80%. The first coat of primer dries at room temperature in 1-2 hours. The metal can only be re-treated once the applied coating is completely dry.

After painting, the material should not be bent or subjected to mechanical stress.Due to this, the integrity of the protective layer will be violated. Enamel, as noted above, does not tolerate bending loads.

Consumption rate per 1 m2

The consumption of enamel per square meter is 120-150 grams. This parameter depends on the thickness of the corrosion layer, processing features and the type of material to be painted. When applying the second and third layers, the consumption per square meter is reduced to 100-110 grams. It is not recommended to exceed the allowed email delivery rates.

Storage conditions

XB-0278 Enamel Primer can be stored within one year from production date. In order for the composition not to lose its original characteristics, the product should be stored in a dark room away from direct sunlight. The temperature at which the product can be stored should not exceed -25 to +30 degrees.

Also, do not place the primer in a room with high humidity and near heating devices. In addition, it is necessary to protect the product from contact with precipitation. After opening the box, the composition should be used within a few hours.

When working with a primer, it should be borne in mind that the solvent evaporates quickly. Therefore, after mixing the working composition, you should immediately begin to apply to the prepared surface.

Precautions for work

The main danger to humans is not enamel, but the solvent that is added to the original mixture. This product volatilizes rapidly. Therefore, it is recommended to wear protective gloves, goggles and a mask that covers all respiratory organs before starting work.

It is forbidden to paint metal with primer-enamel near open sources of fire. This product is highly flammable. This also applies to the area of application of the primer. Surfaces should also be kept away from open sources of ignition. Work must be carried out in a well-ventilated area. If the enamel comes into contact with mucous membranes and skin, the contact points should be rinsed thoroughly with water. If the primer gets into the body, consult a doctor.