Types of paint suitable for a spray gun and how to thin them correctly

A spray gun or spray gun allows you to apply paint to different surfaces: wood, metal, concrete, artificial stone. An important condition for working with the device is the use of such paint and varnish material suitable for its physical properties. If the composition is too thick and dense, it will not pass through the nozzle, but clog all the inlets.

Advantages and disadvantages of spray painting

Spray gun, paint gun, paint sprayer - these are the names of the same device. It is structured differently, but the basis remains the same. The spray gun has a center of gravity to the handle so that the hand of the person holding the spray gun does not get tired during operation.

In addition, the gun is made of special corrosion-resistant materials. The nozzle and stop needle are overstressed parts and should be made of wear-resistant materials.

Spray guns are used in production and at home.To learn how to paint a surface with a spray gun, you do not need special skills, but you must follow certain rules.

Pigment guns have advantages and disadvantages.

| Benefits | Defaults |

| Accuracy of mass application | Price |

| Ability to paint hard to reach places | Requires multiple coats if thick, dense coverage is required |

| Economic consumption | |

| Ease of use | |

| Paints of different composition are used |

Although working with a spray gun is much easier than with a brush, the preparation and selection phase of the base mixture is time consuming.

What paint is needed

For a spray, a composition is suitable that will meet certain requirements. A special condition when working with spraying is such a characteristic as viscosity.

Alkyd enamels

These compositions are sought after. They are used to coat metal, wood or concrete surfaces. The advantage of alkyds is a diverse range of colors, which are selected to your taste. Alkyd spray gun mixtures require a solvent. White spirit is most often used.

Alikdny paints or enamels are composed of highly dispersed pigments. Characteristic of enamel - fast adhesion and film formation. The solvent is already in the formulation, but a more liquid formulation is required for use in the gun.

Acrylic paints

Acrylics are based on polymer esters. They are easily sprayed from a spray gun, but they are not always convenient to use. Acrylates are suitable for painting decorative panels or panels.

The paint hardens quickly, dries in minutes.To dilute the acrylate, it is enough to pour clean water into the working solution.

water-based

This is a budget option that is used at different stages of repair. To control viscosity and density, water-based mixtures are diluted with water.

Oil

The main advantage of oil paints is the brightness of the shade.The compositions are highly toxic: they have a pungent smell that does not fade for a long time. Oil paints require careful dilution with special solvents. If the solvent is poured, the composition will become very liquid. A dense, oily mixture will not pass through the nozzle.

Nitroenamels

Nitro enamels are most often used for painting a car, so the use of a spray gun becomes fully justified. The body is covered with a still dense layer. By using a solvent, it is possible to obtain an appropriate composition density.

Solvent Selection Criteria

If the spray liquid is too thick or too thin, it will be inconvenient to handle. Defects appear on the surface, so you have to redo the work.

The solvent acts as a viscosity regulator. It is necessary for working mixing for many reasons:

- Viscous and thick paint does not adapt well to a metal surface and it is impossible to distribute it in a thin layer from a spray gun. The result is an increase in mass consumption.

- If the mass is liquid, then after spraying it will flow down, forming ugly spots.

- Slime paint will not cover canvas defects when you need to paint a gate or fence. Any unevenness will be visible even when spraying at close range.

- If the composition is excessively liquid, several approaches will be required to create a dense layer.

The correct dilution of the working mixture can be carried out with a solvent with the appropriate properties. The classification of the paint helps in selecting a solvent: lightly loaded, medium loaded and heavily loaded. Too much solvent should not be used for low fill paints, and up to 30% solvent is added to high fill paints.

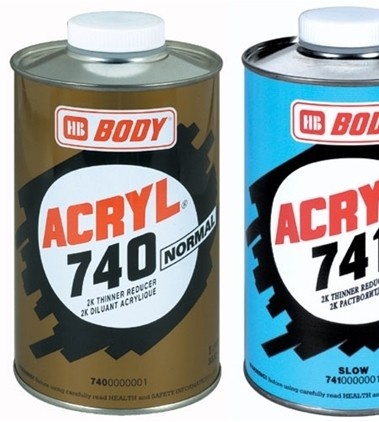

The characteristic temperature of the structure is important. The temperature indicator is taken into account at the start of the dilution step. Solvents are divided into 3 groups:

- fast;

- universal;

- to slow down.

The basis of this classification is the rate of interaction of the solvent with the base composition. Fast solvents are used when the air temperature is below + 17 degrees. If the air is warmed up to + 20 or + 25 degrees, use universal solvents.

When the temperature is above + 25 degrees, the best option is to add a slow solvent.

Dilution Instructions

Usually the manufacturer writes the paint thinning rules on the package. These are standard formulas developed by engineers. For example, when acrylic paints are used, the required minimum is added, since acrylics already contain an activator.

The generally accepted rule is to add 1 liter of thinner and 0.3 liter of hardener per 2 liters of paint. To avoid taking measurements with the naked eye, use a beaker or flask. It is important to respect the spray paint proportions at each stage so that the working mixture is suitable for use.

Another option for determining the viscosity of the working mass is to use a viscometer. With its help, the composition is diluted until the required indicators are obtained.Thinning the paint is much easier than thickening it, so the solvent is added in small portions.

First, the paint is poured, then the solvent is added, following the instructions. After each addition, the working mixture is thoroughly stirred.

How to correctly determine the readiness of the paint

The readiness of working personnel is determined by the naked eye. The paint should flow, but not flow in a strong jet. In addition, the drip rate should be as comfortable as possible, given the diameter of the sprayer nozzle.

The viscometer makes it possible to determine the viscosity with an accuracy of 0.1. The device's unit of measurement is the DIN. It is the relative viscosity that is taken as the basis. The essence of the measurement method is to determine the speed of passage of the working composition through a nozzle of a certain diameter in a given unit of time.

Using a viscometer:

- The container is filled with paint, blocking the bottom hole.

- First, the time is recorded, then the shutter is removed from the hole.

- Once the container is empty, the stopwatch is stopped and the result is recorded.

- The resulting total is checked against a special table and the viscosity is determined.

The table comes with a viscometer. It provides characteristics of paint and varnish composition, as well as flow rate.

Calculation of paint consumption

It is known that the consumption of facade or decorative paint is calculated according to special formulas. In this case, the characteristic of the painted surface is important. Plaster will require more paint than metal siding.At the same time, for a wooden surface, especially if it is not additionally treated, you will need 3-4 times more paint than for primed walls.

The manufacturer indicates the approximate paint consumption on the package. During production, technologists measure the level of viscosity, calculate the flow rate additionally, so you can rely on this information.

Solve common problems

Often the paint is poured into a spray bottle, and the composition turns out to have the wrong consistency. The situation can be rectified only at the initial stage, when the liquid has not thickened.

Ways to solve the problem with consistency:

- If the mass is too liquid, it is left for several hours with the lid open to thicken.

- Viscosity is increased by refrigeration. Lowering the temperature will result in a thicker mixture.

- If the paint is white, you can thicken it with chalk or limestone.

- In a separate container, the pigment is dissolved with a few drops of solvent and mixed with the base composition.

If the listed methods did not help to thicken the composition, you can use an electric spray gun. The nozzle size of an electric paint gun is smaller than that of a hand-held device. This technique does not change the density of the working mass, but even makes it possible to apply liquid paints in an even layer on the problem surface.

A common problem encountered when using a spray gun is coating opacity. This is due to the ingress of water into the working mixture. This happens for several reasons:

- low indoor temperature;

- use of poor quality solvents;

- violation of the rules of operation of the spray gun.

Water penetration leads to poor quality, muddy shade.The solution is to spray thinner with a spray gun after the surface has dried and buff for a fresh coat of corrected paint.