Dimensions and drawings of stepladders and how to make them yourself

Living rooms often have limited space, which forces the use of hanging shelves, furniture with mezzanines. To reach them, you need support, which also requires space to store. Having a stepladder in the household helps solve the problem. A functional product can at the same time be an element of a home interior.

What is a wooden step stool

The stepladder resembles a stool or a chair. Unlike standard samples, furniture elements have steps. Support bars can be permanently attached to the main frame or hidden under the seat or behind the backrest. Wooden products are not inferior to metal structures in terms of strength and reliability, and are superior to plastic ones.

Wooden running boards must have the following properties:

- Vertical stability, regardless of height above the ground.

- Strength of frame, seat, steps in relation to weight load.

- Reliable fastening of folding mechanisms.

Decorative qualities depend on the design features of the product, the type of wood and the method of finishing.

Apps

The first ladder stools appeared two centuries ago in the libraries of the wealthy to facilitate access to high shelves. Over time, they became popular among the rest of the population, who appreciated their practicality and convenience. Wooden products have proven to be indispensable in the kitchen, pantry, garage.

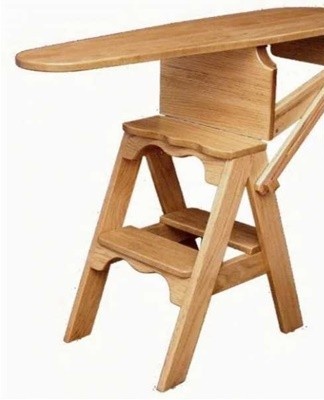

With such support, it is safe to harvest crops in the garden. A stool with steps can be used both for its intended purpose (a chair for sitting down, a stepladder) and a stand for a pot with indoor plants, flower vases, pots and pans. ceramic.

Varieties

Wooden displays come in the form of stools with retractable or non-retractable steps, chairs and transformable stairs.

High stool

A stool with one or two fixed steps corresponds in height to a bar stool (70-75 centimeters). The width of the seat and the steps differs slightly. In terms of strength and reliability, the furniture element is not inferior to other structures. It can be used as an element of the kitchen interior, where there is a bar counter, as a rack in any room.

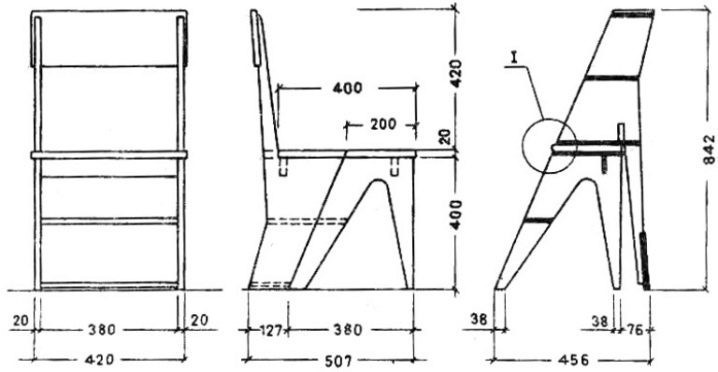

Convertible chair

A transformable chair with the help of a simple manipulation (folding the backrest forwards or backwards) turns into a stepladder with 2-3 steps. A product with a height of 45-50 centimeters is turned into a stable ladder rack with a working height of up to 3 meters (1 meter above the floor surface with an average height of a person with a raised hand from 2 meters).

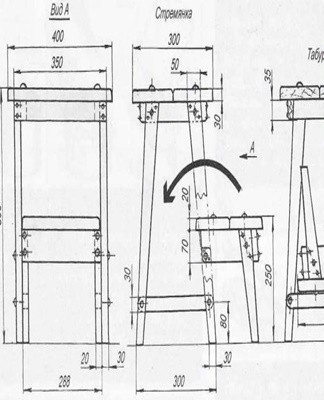

Convertible ladder

The convertible wooden staircase resembles a high stool. The rails are hinged so that the steps can be brought up to the seat.

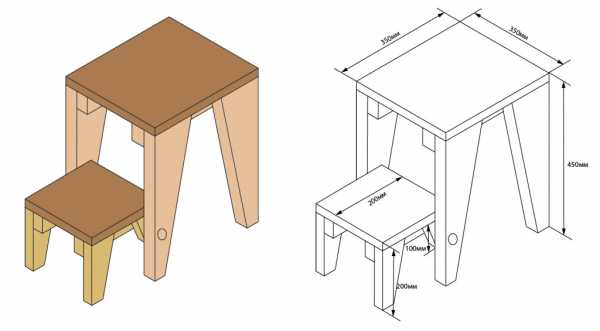

Stepladder with screw module

The screw mechanism allows the steps to be removed under the seat. The product is not inferior to transformers in terms of compactness. The height of the stool is 45-70 centimeters. The number of steps is 1-2.

DIY Dimensional Drawings

Drawings can be developed by yourself if you have experience, or you can use Internet options. When choosing a project document, you should pay attention to the elaboration of details and the availability of all sizes.

An example drawing of a folding stepladder chair:

How to do it yourself

The manufacture of furniture requires certain skills when working with tools, the ability to work with drawings and knowledge of the basic requirements for the quality of the work performed.

Tools and Materials Required

For the manufacture of wooden products, you need tools at hand for cutting, grinding, drilling, fastening, painting. A set of tools for carpentry work:

- metal saw;

- Sander;

- Screwdriver;

- hammer;

- Electric drill;

- paint brushes;

- pliers.

If the design contains parts with a complex configuration, you will need a jigsaw. The presence of an electric jointer and a circular saw facilitates and improves the quality of carpentry work.

Consumables (adjusted by model):

- drill;

- carpenter's glue;

- self-tapping screws;

- screws;

- pegs;

- Sandpaper;

- varnishes and paints;

- loops.

The choice of solid wood depends on the preferences of the manufacturer.

You can make a wooden stepladder from the following types of wood:

- pines;

- birch;

- linden;

- acacia;

- walnut;

- Oak;

- beech.

Pine is the most affordable material. The wood contains resin, which requires additional treatment before painting.

The most economical option is to use multi-layer plywood.Sheet thickness of 2-3 centimeters can withstand a weight load of up to 80 kilograms.

Preparatory work

First you need to decide on the type of product, find or make the most detailed drawing, which indicates the dimensions and number of parts.

Based on the project, a calculation is made:

- by the amount of wood;

- Stationery;

- Components.

The manufacturing technology and the tool required for it are determined.

Procedure

According to the drawing, you can prepare patterns for the curly parts of the furniture-stairs.

The sequence of operations (can be adjusted depending on the step model chosen):

- The necessary parts are cut from the array of canvas or blanks.

- The parts are sanded, including the ends (for cutting plywood - cut edges).

- Carpenter's glue is applied to the ends of the step blanks, connected and fixed until completely dry in clamps.

- Marks are made on the legs to drill holes for the fixings.

- Holes are drilled for the connections.

- Make the assembly.

The assembly begins with the side guides, to which the legs and steps are attached. The top step is installed last.

An example of making a stool with a screw module

Untrimmed panels or used building materials are used as the starting material. The surfaces of the boards are leveled on the machine, cleaned of layers. The marking for the seat and the cutout are done. The inner edges of the parts are treated with carpentry glue, joined into a single board and clamped with clamps. After drying, the fabric is sanded on all sides and ends.

Sitting legs (4 pieces) are cut according to patterns or markings. Are polite.Then two czars are cut (plank joints for the legs) The czars are connected to the legs: adhesive and self-tapping screws (2 per leg). The seat is attached to the side bars with self-tapping screws (8 pieces on each side). The main frame is ready.

They begin to step from the crossbar. Mark, cut to size. If the width of one part is not enough, two parts are glued together, fixing them in clamps.

The legs of the steps are cut in pairs of different lengths. Sharpening. They are connected by drawers: long with short (for screws and glue). Holes are drilled in the short legs for the installation of hollow wooden tubes. The crossbar is installed and fixed with recessed self-tapping screws.

Fastening of the short legs of the step to the legs of the stool is carried out using self-tapping screws screwed into the hollow tubes. The height at which the short legs connect to the legs of the stool should match the height of the long legs of the step. Two lower drawers are installed on the legs of the stool. The product is ready for finishing.

Finishing

When the product is completely ready, the decorating process begins. The corners at the ends of the legs, seat and crossbars are pre-cleaned with sandpaper. Depending on the texture of the wood, the surfaces are tinted, varnished in 2-3 layers. Make sure the polish is completely dry before applying the next coat. The plywood is painted with oil paint in 2 layers and varnished.

Additional tips and tricks

When using a non-edged board, before cutting the parts, it is necessary to level the base surface so that the board lies flat and there are no deformations when cutting. the cup. Curved parts should be cut using plywood templates.

The seat, steps and frame can be made from different types of wood or using sheets of plywood.

Standards must be observed to guarantee the safety and reliability of the use of ladders:

- the height between the steps is 15-20 centimeters;

- tread widths 20-25 centimeters;

- the dimensions of the seat are at least 30x40 centimeters.

The foldable kitchen chair/stool should be the same height as regular chairs and stools. The functional element should not stand out in the interior of the kitchen by its color or decor. For example, a wooden product will look alien in a high-tech room. Interiors in the style of Provence and Art Nouveau are suitable for him.