What can be glued with a glue gun and how to use it, selection rules

A special gun soldering iron with glue allows you to attach parts to each other, speeds up the installation process. Such a device is used by housewives who make various handicrafts and is used in workshops. Hot glue creates a strong seam. Its color can be chosen according to the wishes of the customer - from milky to silver. And changing the rod takes less than a minute.

Content

- 1 What is it and how does it work

- 2 Key properties when choosing

- 3 Appointment

- 4 What glues

- 5 Main Manufacturers

- 6 What glue to use

- 7 Read the instructions

- 8 Price categories

- 9 If you haven't read the instructions

- 10 Advantages and disadvantages

- 11 Important points when using

- 12 Security engineering

- 13 Possible errors

- 14 How to properly change rods

What is it and how does it work

The glue gun is one of the simplest electrical equipment. A plastic rod inserted in a special compartment is pushed through the heater assembly and the nozzle. At the outlet, a molten flux is obtained which solidifies rapidly in air.There are several modifications, depending on the size of the glue stick:

- 11 millimeters (household);

- 16mm (industrial).

There are also 7mm rods, but they are rare. The power of heat guns varies greatly - from 15 to 100 watts. Size and function change accordingly. But the main task remains: to melt and push the glue.

Design

The body of the heat gun consists of 2 halves fixed with a hole for installing a rod (on the back), a nozzle and a toggle of the trigger button. Everything is simple, no frills. For convenience of work, a collapsible spring support is installed in front. Sometimes the gun is equipped with a toggle switch. The device is simple and reliable. More sophisticated models of thermo-guns are equipped with temperature control (positional, step, electronic). There are also battery-powered models.

Principle of operation

In principle, the glue gun is similar to an electric soldering iron. A heater combined with a nozzle gradually melts the plastic. The rod, inserted into a special handle, gradually penetrates deeper and deeper into the heating assembly. Hot glue is expelled through the spout, a new batch is dispensed by pressing the start button.

The disadvantage of the simplest designs is that the unit is constantly in operation. Plastic drips can clog the nozzle and should be cleaned periodically.

Key properties when choosing

The gun is selected based on the purposes and tasks it needs to perform. For crafts, the most simple and low-power will do. For repairs, a more serious unit will be needed. The same goes for the diameter of the working rods. The most common - 11 mm. Smaller ones are less common, large ones are used in industrial products.

It will not hurt to have a switch and a bracket for fixing the "idle" gun. It heats up quickly, so there's more benefit from a toggle switch than harm. When choosing, do not buy the cheapest, unsightly and poorly packaged guns: they will not last long. It is better to favor products that are legally manufactured, with details of the goods and a guarantee in the event of a breakdown.

Check valve reliability

The presence of a special device - a check valve - allows you to extend the life of the gun and get rid of unpleasant glue drops. Its reliability directly depends on the class of equipment and manufacture, as well as the handling of the device.

A check valve is a special ball that blocks the flow of glue into the nozzle. To increase the resource of the assembly and the gun as a whole, it is necessary to periodically clean the internal channels from the mass of frozen glue.

Glue warm-up time

This indicator is not the same for different models. It is associated with power, the presence of a heating regulator, the type of glue stick. On average, this is a period of up to 5 minutes. Industrial designs, with a powerful heater and melt temperature changing function, are ready to deliver liquid glue faster than their smaller counterparts.But the price difference between them is also considerable, and this also influences the choice of a housewife or a "Kulibin" craftsman.

The presence of nozzles and extensions

Additional devices or additional parts always have a beneficial effect on the operation of the unit, as they expand the arsenal of its skills. In the case of a gun, these are replaceable nozzles with different outlet diameters, special extensions. Their advantages are undeniable: penetration into hard-to-reach places, regulation of the portion of glue pressed at the push of a button. Unpretentious models are usually not equipped with such accessories, only expensive and professional ones.

rods

They differ in diameter (7 or 8 millimeters, 11, 25 and so on), melting point, color. Saving on normal rods in favor of poor quality and cheap rods threatens uneven fusion, the appearance of "snot" stretching and a decrease in the strength of the seam. Colored glue sticks are needed to create appliqués, volumetric figures, fix some interior details.

Standard rods for all occasions - milky color. They are used by 90% of gun owners. Before buying consumables, you need to know what standard size a particular piece of equipment works with. The rod is not a pencil, it will not work to whip it and somehow stick an 11mm in a gun for 8mm.

Chamber size and heating element power

The hot melt glue gun is designed so that the size of the heater, the "furnace" for heating the rod and the power correspond to the dimensions and class of the device. The smaller 15 watt guns have enough room to work with a 7-8mm rod.Solid models are designed for larger size, which means they will quickly heat up the piece of glue and get it ready for work. It's pure physics that also applies to glue guns.

wire length

It seems insignificant in comparison with other parameters. But it is not practical to work with a "short wire" gun: you have to be directly near the socket. The question is solved by connecting an extension cord, but why do that if you can buy a gun with a longer power cord length?

Availability of replaceable nozzles

Another bonus that will be appreciated by those who will work a lot and often with a glue gun. The nozzle is clogged, there is no time or desire to clean - the "spare wheel" will help you. It also happens that the nozzle is damaged beyond repair, clogged with glue, and the working unit is urgently needed - changing the nozzle will also help. The total resource of the gun depends precisely on the condition of this unit (without count the heater).

power regulator

The presence of a rod melting temperature control function will be appreciated by those who do not have it on the gun. It will melt everything at the same rate, regardless of the type of plastic loaded. And the advanced adjustable "RPM" gun is convenient in that it saves energy and varies modes according to the characteristics of the glue stick.

Nozzle type

Most guns are equipped with standard light alloy nozzles covered with a silicone sleeve. Variants with different nose lengths are available for ease of use for surface and deep glue application.The useful diameter of the rod corresponds to a certain value of the passage of the glue through the nozzle, as well as to the dimensions, standard size of the thread for fastening to the gun. It will not work to put a nozzle of a "small" unit on a "large". In the simplest gun designs, the nozzles are non-removable and connected to the heating chamber.

Appointment

Glue guns are intended for decoration, assembly and professional activities. There are even devices for straightening body parts: with the help of strong glue, dents in the coating are removed. There can be no universal guns. It is necessary to immediately decide where the hot melt unit will be used, and only after that proceed to the choice.

Decor

The glue gun has long been used to create decorative panels, compositions for quickly and reliably fixing parts on a plinth, wooden or metal surface.

repair

Another area where glue guns are used. It is not necessary to use standard methods for gluing the tiles to the floor, fixing the suspended ceiling, fixing the wooden block to the stone wall. 5 minutes of gun work - and the part is in place.

needlework

A strip of glue from a gun glues fabric, yarn products, knitwear, connects embroidered paints to the base. The polymer mass replaces conventional synthetic adhesives and surpasses them in terms of strength and speed of joint curing.

Building

Carpet fixing, installation of electrical equipment, reliable fixing of plumbing fixtures - and this will help the glue gun. Polymer rods have high adhesion to anym surfaces. You just need to clean them from dust, degrease and dry them.

Warehouses and movers

The device is suitable for temporary fixing of structures in a warehouse, creating an instant connection between plastic and metal, wood and glass. A powerful gun is enough to apply glue in a small warehouse ladder. You can fix the details in points, in a strip, along the contour - there are enough options for a solution. It is also convenient to mark the goods with colored rods, creating a strip of glue in the desired place.

Daily life

Repair broken dishes, glue tiles, flooring, repair the countertop. To do this, you don't need to keep several different synthetic adhesives on the farm.

The presence of a compact and reliable gun with a set of rods immediately solves all the problems of a home craftsman.

Plastic and PVC models

And with the help of melted glue, it will be possible to quickly and reliably fix plastic parts. But not at all. There is a limitation on PVC; hot melt will not restore a torn shower curtain.

Fabrics

Such a complex and inconvenient to glue material, like fabric, with rare exceptions, is successfully connected using a heat gun. It does not matter the choice of the base, the combination of fibers - for hot melt glue they are all equivalent, they stick together easily.

Concrete, plaster and similar materials

One of the rare exceptions, white spots, for which a glue gun is not suitable. It will also not work for bonding plaster, for creating a strong joint between the concrete surface and another structure (paper).

What glues

Rubber-like thermoplastic mass easily bonds materials of different structure and origin. Paper, wood, cardboard, glass or rubber are all within reach of a glue gun.

Paper

Instant, effective paper adhesion with a quick-setting compound is no problem. It is much easier to attach a sticker, create an airy openwork composition or an ordinary envelope with a heat gun by hand than in any other way.

Cardboard

Cardboard, being a denser material, is more difficult to glue with ordinary mixtures than paper. But with hot glue it's easy. The stitching is durable, water-resistant and load-bearing. A big plus of the technology is that there is no need to wait for the solvent to disappear (the glue to dry). This greatly speeds up the assembly process.

Ceramic

Apply a layer of glue to one half of the broken cup, then to the other half, wait 15 minutes. You can forget about such a technique forever if a glue gun appears on the farm. Wait for it to warm up, a drop or a strip of hot melt glue on the contact areas, press firmly - and the product is like new.

TREE

The strong adhesion of the plastic mass allows you to easily connect the wood to each other, fasten the bars to other materials. Before work, you need to make sure that the surface is free of dirt and dust, dry and degreased.

polystyrene

Polyfoam is a difficult material to glue, it requires the use of special compounds. This does not apply to hot melt equipment. We load the rod into the gun, turn it on, pull the trigger. Then, at least the ceiling tiles, or even the strips, are glued. Clings instantly.

Glass

Another problematic substance for which it is difficult to create a strong seam. It is not only difficult, but sometimes impossible to connect glass parts together, to close a crack, to attach a plate to another material without a glue gun.

Rubber

Quickly glue the rubber without using special technologies and without waiting several hours for the seam to gain strength - it was impossible to think about this before. Melted glue from an electric gun fixes the problem in seconds.

Metal

Ferrous and non-ferrous metals have always been difficult to bond. For this, synthetic mixtures, epoxy compounds are used, which have the greatest resistance to seams. But the bonding time is also considerable. Using a gun with a set of rods saves energy, time and nerves.

Main Manufacturers

In the market of glue gun manufacturers, a kind of ranking of trusted brands has formed. Which to give preference is the user's choice. Sometimes buying a no-name model is justified if you need a tool for a while. In case of failure, it is not a shame to throw it away later. But the marriage between these "masterpieces" of the Chinese shirportreb is formidable.

Dremel

A solid North American brand, famous for its high-speed grinders, which they began to call - Dremel. Heat guns of this brand are reliable and fully justify the money spent on them. A switch is integrated into the handle, a special bracket is created in the front part. Replaceable nozzle. It is convenient to work with such a gun, and it will last a long time. Dremel users, all as one, note the ergonomic handle of the device, its lightness. But the original glue sticks are not cheap.

Steinel

The German scruple, the full conformity of the declared characteristics with the real ones. Such a gun, bought for crafts or home repairs, will not let you down. Designed for 220V home network.There are models with temperature control, as well as rechargeable models. By the way, self-contained Steinel guns are considered one of the best: they contain electronic temperature controllers, an automatic shut-off unit.

Bosch

Bosch company products are known and respected far beyond the borders of Germany. Household and professional tools of this brand are reliable and trouble-free equipment. The products use high quality components. We offer solutions for amateurs and pros. The gun fits comfortably in the hand and is equipped with an electronic stabilizer.

Glue sticks are produced under the brand of the same name, which are distinguished by stable quality. There are network guns and rechargeable compact guns.

Hobby and pro

Models of the middle class for universal use are produced. The gun is equipped with a switch and has good ergonomics. Of the obvious advantages of the gun, the low price is called (700 rubles). Allows to block leaks of the adhesive mass.

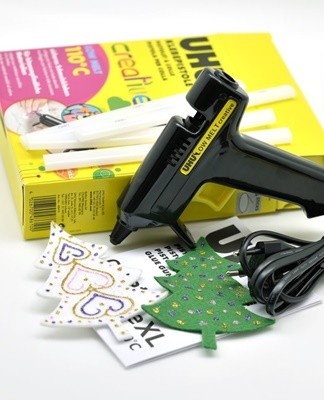

UHU

Another middle peasant. Super quality should not be expected from the products of this brand, but the hopes placed in them will justify the heat guns. They are classified as low temperature (110 degrees), suitable for household and craft purposes.

Master's hand

Cheap and cheerful - this is how you can describe the products of this manufacturer. Not Bosch, but suitable for home crafts. There are no additional functions, including the power toggle switch. There is also no regulator. One of the simplest and cheapest guns, that's where its benefits end.

Stavr

Russian manufacturer. Produces pistols with good ergonomics, a replaceable nozzle and a comfortable rocker button.Among the undoubted advantages is fast heating (about a minute). Temperature control to melt glue is not provided.

Defort

Glue guns with conflicting ratings. Judging by the complete case and spare attachments (2 pieces), this is a tool for professionals. The slightly curved handle leaves a pleasant impression. But the price (up to 2000) and the design of the case are not particularly encouraging.

Kolner

A brand with mixed Russian-Chinese roots. The manufacturer provided for the presence of a switch and lighting of the working area, equipped the gun with a long power cable. And the price of the product does not "bite". In its price range, Kolner "crushes" its competitors with an additional set of functions, they have almost no backlight and a rocker switch. Not to mention the removable and spare nozzle.

What glue to use

Good stitching requires quality glue. On the other hand, there is no point in buying expensive Bosch or Dremel rods for a simple gun. The choice of color depends on the nature of the work: colored glue is used for needlework, modelling. For repairs, a regular yellow will do. Different rods do not have the same melting point, and this indicator is related to the characteristics of the gun. A "weak" unit will not support refractory glue. And, of course, the diameter of the rod must correspond to the size of the pistol grip, this is an immutable axiom.

By color

The choice of color is important where it participates in the composition, you cannot do without it. In other cases, yellow "work" glue sticks are used, resulting in a strong, neutral shadow joint.

Yellow transparent rods

It is a "universal soldier" for most problems.The yellow stem is more often used for working paper and cardboard, wood.

Multicolored, opaque

This group of glue sticks, oddly enough, is also considered universal. This is explained by the fact that the tint is necessary to mask the joint for the color of the parts to be assembled.

Clear adhesive

Transparent rods in white color are the most demanded. They are supplied with glue guns and will be sold in hardware stores by default. The most common consumables.

Gray or black

Darker shades of glue sticks create a layer of insulation, used as a sealant. In terms of quality characteristics, these glue sticks are not much different from others.

Opaque white

When a gun is needed for working with metal, glass, joining white parts, you cannot do without glue sticks of the appropriate shade. Sometimes used as a marker.

By temperature

When choosing a glue stick by color, another important feature should not be overlooked - temperature. It is indicated on the packaging with the glue sticks, as well as in the specifications of the gun. It is measured in the range from 100 to 150 degrees, so the use of "blind" glue, which was at hand, has unintended consequences.

It is always best to check the type of glue stick and match its melting point to the capabilities of the gun.

Read the instructions

The condition most hated by Russian users. As a result, the gun that worked in the store at home for some reason refuses to cooperate, and the cheaply purchased rods do not want to melt normally, they drip and shoot. Most of the problems with technology are hidden precisely in the lack of knowledge about the principles of its operation.If the instructions say that the glue gun can't be left on for more than half an hour and it's worth putting it down, then that's exactly what you need to do.

Price categories

The prices of guns, as well as any tools, vary to a large extent. There are simple ones, for 600 or even 400 rubles, and mannequins for 2,500 people meet. In the lower range there are unpretentious products with a minimum of options. The exception is Kolner with a long cable, a replaceable attachment and a switch button on the handle.

The cheapest Dremel will cost 800 rubles, while it does not contain any additional features. Convenient and productive models of self-powered guns (built-in lithium-ion battery) from Bosch or Steinel cost 2400-2500 rubles. For comparison: a Bosch high-temperature network gun costs 2.1 thousand rubles.

Aggregates with a value greater than 5,000 are considered professional. If you need a gun once, you can find a model for 300-400 rubles, "one day", since among such products the MTBF is low. They are not even repaired, they are simply replaced with new ones.

If you haven't read the instructions

Basically, the glue gun is not a space shuttle or even a supercomputer. It is difficult to spoil it with involuntary actions. It is enough to act by trial and error, respecting the simple basic rules. And the process of mastering the glue craft begins with preparation.

Coaching

You bought (rented from friends) a glue gun. I don't know or I forgot how to use. First remove the unit. To do this, the gun is removed from the blister (cheap and household models), from the suitcase (professional).The "gun + glue" set must be folded. This means that the accessory is installed, the stem selected and plugged into the outlet. Standalone models are charged until the battery is completely ready. For models with manual temperature control, the regulator is set to minimum. For those equipped with a toggle switch, you need to press the key, transferring it to power mode. And only after that you can start field testing.

Usage algorithm

The method of using a heat gun is simple to the primitive: wait the prescribed time for the rod to heat up, press the button, squeeze out a bead of glue, release it, then press it to new. It is not necessary to press hard on the lever to try to speed up the flow of incompletely melted adhesive. This impatience will cause the gun to break.

By directing the nozzle and working in synchrony with the rod push button, they form a layer of glue on the part (fill the joint). The length of the rod is not infinite, so at the same time they monitor the consumption of glue, adding new cartridges in time. Sometimes the glue comes out with a characteristic cotton ball, it's not a breakage, just air. The rod should rest firmly in the handle, pressing against the chamber. As it warms up, it moves forward. Before changing the type of rod (color, melting point), it is advisable to clean the nozzle.

To do this, the gun is left to cool, disassembled, cleaned with a wire or a pin. The same procedure is recommended when stopping work with the gun. The nozzle is the hottest part of the glue gun. On some models, the case heats up noticeably. On average, the glue has a temperature of 100-110 degrees.

Rough handling may cause burns. Therefore, compliance with personal safety requirements (gloves) is a prerequisite. The glue sets in seconds and some skill is required to work effectively with the gun.

Usage time

The average duration of using a glue gun is 30-40 minutes, depending on the model and the individual characteristics of the device. For different products, the body and the handle do not heat equally, it also affects the running time. Another limiting factor is the length of the glue stick. Usually, once the glue cartridge is used up, it is advisable to clean the nozzle before installing a new one. This will be the run time of the gun. In perfect designs, the heater does not stay on all the time. When idle, it automatically goes into sleep mode to save power and extend the life of the gun.

Advantages and disadvantages

A glue gun is an easy thing to use. With its help, it is easy to connect the parts together in the craft, to close the joint and to glue the floor covering. But there are no truly universal models that can be used in any situation.

Pistols differ in shank diameter, feature set and sizes. It is impossible to get a complete set for the minimum price, and an expensive and fully equipped unit is not always needed on the farm. And it makes no sense to buy a gun for 2.5-5 thousand, if it is possible to get by with a cheaper analogue.

Another weak point is the need to select rods for a specific type of work, gun settings, mode, and this is not always convenient.

Important points when using

The glue stick should be carefully inserted into the gun, making sure it adheres to the rubber band. The nozzle passage clogged with frozen glue is the cause of breakdowns, breakdowns of guns. Therefore, you should make a habit of cleaning the accessories after finishing the job. If the gun is not in use, it should be turned off. In models with a toggle switch, this action is performed by pressing a button, in classic models, the plug is removed from the socket. The position of the gun in the rest position - nose down, on a special stand and nothing else.

Security engineering

Individual parts of the gun are heated to a temperature of 100 degrees or more. Bare-handed contact with them is unacceptable. The same rule applies to melted glue, so household gloves are a necessary protective measure.

Possible errors

These include the wrong choice of the mode of operation of the heat gun and the rod (it melts for a long time), the use of low-quality glue cartridges. For regulation models - work at the maximum (minimum) position, which does not correspond to a specific type of rod. In addition, beginners often forget to charge the battery on rechargeable models or firmly insert the device into the holder (for products with a detachable cord), and then complain about the poor performance of the equipment.

How to properly change rods

The glue stick is changed by pressing the rocker: the remnants of the cartridge are squeezed out, removed from the heat gun and a new one is inserted in its place. After that, it remains to press the hook several times, moving the rod towards the camera. Sometimes it is advisable to run your beak over a piece of cardboard to remove the inevitable drops of glue.