How to repair a muffler with high temperature sealant, description and composition

High temperature muffler sealant is used for emergency repairs of individual parts of the exhaust system. Thanks to him, car owners assemble already repaired elements, fill holes and cracks in parts. In order for the purchased composition to meet the requirements and not fail at the wrong time, it is important to know what these products are intended for, what to look for when choosing and how to use it correctly.

Description and purpose

High temperature sealant is a kind of glue used to process parts. It makes all elements of the system water- and gas-tight, extends the service life of elements, helps to delay overhaul or complete replacement of the muffler and pipes. The product is available in the form of a paste, liquid or tape with a special impregnation. Depending on the purpose and composition, full hardening of the product occurs in 3-12 hours.

Choice criteria

When choosing a sealant, it is important to be guided not only by the manufacturer's promises and the reviews of other motorists, but also by what parts the composition is intended to repair, what temperatures it can withstand, whether the part to be repaired is subject to vibrations or not. Based on this, the car owner chooses a suitable composition, otherwise the exhaust system will need new repairs after a short time.

Operating temperature range

The most important indicator, it depends on how long the sealant will perform its functions. The higher the operating temperature range, the better.

Unscrupulous manufacturers often deceive buyers by stating the maximum permissible temperature at which the composition will perform its functions only for a short time.

In order not to be mistaken with the choice of sealant, it is important to carefully read the information on the package and pay attention to how long the composition will remain stable at the specified temperatures.

State of aggregation

All high temperature sealants are divided into silicone and ceramic; the resistance of the product to constant vibration and vibration depends on the composition.

Silicone

Used in spacers between parts. After the composition is frozen, it remains somewhat mobile, so it is not afraid of constant fluctuations.

Ceramic

Used to fix cracks, holes and rusted parts. After complete drying, the composition becomes solid, which is why it does not withstand constant fluctuations. It is best to use this sealant when repairing fixed parts of the exhaust system.Motorists are more likely to use silicone sealants because they do not crack on moving and stationary parts of the exhaust system.

A type

All high-temperature sealants are divided into several types depending on their characteristics.

To repair a car's exhaust system

The basis is fiberglass, to which manufacturers add additional substances. A distinctive feature of sealants is the hardening time, it rarely exceeds 10 minutes. Compositions tolerate high temperatures well, but crack under constant vibration and shock, and are designed to eliminate damage to the exhaust pipe

Assembly paste

The composition hardens quickly and does not lose its properties even due to high temperatures. Used when installing new or refurbished items.

muffler sealant

It is often used as a prophylaxis; it takes some time to fully solidify. It is a versatile product that can be used to repair any part of the exhaust system.

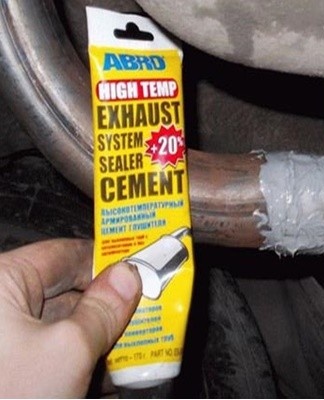

muffler cement

These sealants form a hard layer on the parts and are not afraid of high temperatures. The most durable compound used to repair stationary parts of the exhaust system.

Taking into account the above characteristics, the masters select the desired type of composition based on the existing damage and operating conditions of a particular room.

Review of the best manufacturers

Despite the fact that there are a huge number of different types of sealants on the market, the manufacturers described below are the most popular among motorists and craftsmen.

Liquimoly

The company produces several types of sealants, intended not only for repair, but also for installation.The products do not contain solvents and asbestos, are resistant to high temperatures and have a neutral smell.

Deal done

The brand produces several types of sealants with ceramics in the composition. Thanks to this, all products have increased strength, are not afraid of high temperatures and are excellent for repairing stationary elements.

CRC

The manufacturer produces 2 types of sealants for sealing small and large cracks. Both compositions harden quickly and withstand heating up to 1000 degrees Celsius.

Permatex

The manufacturer produces 3 products for repairing the exhaust system of a car - classic putty, bandage and cement. The products are used to correct both fixed parts and pipes.

ABRO

This manufacturer's cement is durable and is used to repair any type of damage. Suitable for small areas, wear-resistant and not afraid of high temperatures.

bosal

Cement mastic is resistant to vibration and high temperatures, it is used as a putty, it is not suitable for mounting parts. It freezes very quickly, so working with it requires some skill.

Holt

The manufacturer produces 2 types of sealants - assembly paste and composition for repairing the exhaust system. Both products are sold in small packages.The choice of this or that product will depend on the nature of the damage, the experience of the motorist with this or that composition, as well as the volume of the package and the cost of the product.

Application rules

The sealant is only used on a thoroughly cleaned surface. It is necessary to remove not only dirt and dust, but also traces of rust so that the composition adheres well and does not crack in advance.Any sealant is applied in a thin layer, achieving an even coating.

It is important not to ignore the instructions and let the composition dry completely and, if necessary, use additional heat.

Examples of use

Repairing an exhaust pipe or muffler with high temperature sealant will look like this:

- first you need to carefully examine all the details of the system and identify cracks and holes;

- it is important to clean the elements of carbon deposits, dust, dirt and rust for the adhesion of the composition and the metal;

- degrease the surface to be treated;

- carefully open the package with the sealant, put a special nozzle on the tube;

- apply the product to a seam or hole, its thickness should not exceed 2 cm;

- let the putty dry, then connect all the necessary parts;

- in the case of holes, a layer of product must be applied to them and the cracks must be carefully repaired and left to dry according to the instructions.

After the composition is completely dry, the car can be used as usual.

Additional tips and tricks

In order for the heat sealer to last longer and not lose its properties, it is important to remember the following tips:

- the product can only be used temporarily, as it will quickly deteriorate under the influence of constant vibration and high temperature;

- use is possible only when the cracks are outside and well visible, otherwise the system will have to be completely disassembled and replaced with a new one;

- it is important to remember that the putty completely hardens within a few hours, the process can be accelerated with heat;

- the product is applied only in an even layer, the excess is removed or carefully coated, thus achieving an even greater seal.

Correct use of the compound will not only prolong the life of the parts, but will also help to delay the overhaul of the exhaust pipes or muffler.

Alternative methods

Service station technicians do not always use sealant as a means of repairing the exhaust system, because professionals know the means of repairing the muffler and pipes.

cold welding

This is an inexpensive compound that is used to hold parts together and eliminate cracks and holes. When buying, it is important to pay attention to the fact that the product is heat-resistant.

Complete solidification of the composition occurs in 10 hours. How long cold welding will perform its functions depends not only on the manufacturer, but also on the preparation of parts for subsequent repair.

Exhaust rebuild kit

Not intended for major repairs and is an emergency tool. The set includes special tape, thread and adhesive. Such a product is indispensable in the event of a breakdown on the road, and it takes time to get to the nearest garage.

High temperature compound for working metal parts

These are special ceramic sealants containing metallic fillers. Designed for the correction of all details, they are very durable, the only drawback is the price.

High temperature putty will help not only to eliminate cracks and chips, but also to create an additional layer between the parts to be fixed. However, this product is not intended for major overhauls and acts as an emergency measure.A sealed exhaust system will last no more than 2 years, after which it will need to be serviced.