Types of adhesives for plexiglass and rules for use at home

Polymer material is not inferior to silicone glass in terms of transparency, but at the same time it has less weight, lends itself to tinting and mechanical processing. Using glues for plexiglass, they create furniture, stained glass, souvenirs, elements of external and internal structures under construction. Adhesives are needed for small home repairs of thermoplastic products.

What adhesives are suitable for plexiglass

The list of suitable means for gluing Plexiglas is determined by the chemical composition of the material.Plexiglas is a synthetic product, acrylic resin/plexiglass. Distinguish between high molecular weight, low molecular weight and molded polymer. Acrylic lends itself to the action of solvents, cyanates, strong acids.

Under their influence, there are two types of chemical reactions that determine the strength of adhesion:

- The surfaces of the parts soften, mix together and, after hardening, form a monolith.

- The agent is partially absorbed into the pores of the Plexiglas, forming a binding film.

The first method is called cold welding and produces the strongest seams.

Solvent-based acrylic

The adhesive for plexiglass based on dichloroethane is transparent, can have a liquid or viscous consistency. The adhesive softens the upper layers of the parts to be glued, after which it partially evaporates, partially absorbed into the polymer.

An epoxy resin

Epoxy is suitable for filling shallow cracks to restore the surface layer. The middle layer penetrates the pores of the Plexiglas smoothing out any irregularities.

UV

Photopolymer adhesive containing methacrylate (organic glass is a polymer of methyl methacrylate). The hardener is the ultraviolet radiation received from the LED flashlight.

Modifications of UV glues are intended for bonding:

- plexiglass with plexiglass;

- metal;

- TREE;

- Plastic.

The resulting compound has:

- high resistance to mechanical stress;

- extreme temperatures;

- transparency;

- sustainability.

The absence of solvents and non-flammability make it safe to use.

popular brands

To glue plexiglass, agents are used that include solvents, acids, polymers.

Acrifix 116

One-component solvent-based compound (dichloroethane) suitable for bonding cast and molded Plexiglas. Viscous adhesive, transparent, resistant to high and low temperatures. Once connected, it fills the cavities between the parts.

Joint hardening due to evaporation and impregnation of methyl methacrylate. Acrifix is not used for Plexiglas parts with mechanical stresses in bending, compression. Mixes well with Acrifix 117.

Acrifix 117

Adhesive similar to Acrifix 116, with which it mixes easily.The consistency is liquid. Does not form cavities with PLEXIGLAS GS (high molecular weight material).

COLACRIL-20 glue

Liquid product. Does not contain solvents. The connection is seamless, but not as strong and durable as Acrifix.

COLACRIL-30

Viscous composition. To improve fluidity, mix with COLACRIL-20. The downside is cracking at the joints.

Moment

Special instant adhesives contain cyanoacrylate. The tools make it possible to firmly glue plexiglass parts, which are small in volume and weight.

Cosmofen

Liquid superglue for gluing plexiglass. The composition is similar to Moment. The downside is a noticeable seam of short duration.

How to connect with metal

To create a durable joint of plexiglass with metal, use means containing organic resins and solvents, synthetic rubbers. The adhesives produced can be universal (for all surfaces) or specialized.

In order not to be mistaken in the choice, it is necessary to study the conditions of use specified by the manufacturer.

The active components of adhesives can be toxic, requiring care when working with the materials.

Glue brand 88

Glue 88 is a mixture of phenol-formaldehyde resins, rubber, ethyl acetate. A universal tool is used to combine materials of different structure. Modifications used for bonding metal and Plexiglas:

- 88 million;

- 88 NT;

- Following.

General properties:

- viscosity;

- elasticity;

- strength;

- water resistance;

- frost resistance;

- prevents corrosion from developing.

Bonding methods: cold and hot. The essence of warm is to heat the surfaces after applying the composition to 80-90 degrees, after which they are tightly pressed against each other.The quality of the seam obtained by the hot method is superior to that of the cold method.

Dichloroethane

Chemically active substance. It is a colorless liquid that evaporates quickly with a sweet smell. The organic solvent acts on the metal, destroying the surface oxide film and the plexiglass. The result is a strong molecular bond.

Liquid Nails

Liquid nails are used to connect dissimilar materials. Adhesive modifications: latex and neoprene. Neoprene liquid nails (chloroprene rubber and organic solvents) - a means of gluing metal and plexiglass.

The product is resistant to extreme temperatures, high humidity and aggressive environments. The disadvantage of a neoprene product is the unpleasant smell. To use liquid nails, a special device is needed - a gun into which a metal tube with a product is inserted.

A moment for iron and plexiglass

From the Moment line of adhesives for bonding metal and plexiglass, a universal option is suitable: Moment-1. He quickly and firmly grabs surfaces, is not afraid of water.

How to glue wooden pieces

The type of adhesive composition is determined taking into account several factors. First of all, the texture of the wood is determined: the presence of resins, the absorption capacity. It is important to know what loads the glue line will withstand, under what conditions it will be used.

great glue

They work with wood and Plexiglas using cyanoacrylate glue. The exposure time does not exceed 7 seconds, which excludes its use on large surfaces. Glue is irreplaceable when creating artistic compositions from plexiglass and wood.

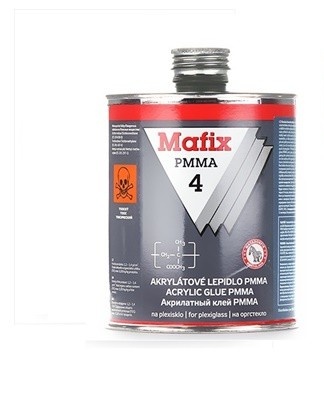

Mafix

Mounting modification adhesive: Mafix Plast VP 5318.Properties: universal. Suitable for bonding surfaces of all materials. The semi-liquid product helps to seal microcracks, creates a line of glue resistant to moisture and ultraviolet rays.

Cosmophene

The adhesive contains cyanoacrylate. The exposure time is 5-8 seconds. Final hardening takes 6 to 12 hours, depending on air humidity. The lower temperature limit at which you can work with glue is +5 degrees. The disadvantage of the glue line is its softening at a temperature of +80 degrees. For this reason, it cannot be used when bonding parts exposed to heat. The liquid agent evaporates toxic substances during operation.

How to make an adhesive with your own hands

Plexiglass bonding agent can be made at home. This will require acetone, dichloroethane, and powdered Plexiglas. In glass/ceramic dishes, mix the liquids in a 1:2 ratio (acetone:dichloroethane). You will need a glass rod or twisted wire to stir.

A piece of polymer is ground and added to the solution, stirring constantly. The viscosity of homemade glue is determined by the naked eye, depending on the intended purpose. After the composition has acquired the desired fluidity and has become transparent, it is left for several hours for final dissolution. Store the product in a container with an airtight lid.

Adhesive properties are possessed by a mixture obtained from the solvent 646 and the foam. Shake the solutions again before use.

General technology and principles of gluing at home

To achieve strong adhesion, it is necessary to prepare the surfaces to be bonded.If it is plexiglass, then the places where the glue is applied are wiped with a rag soaked in gasoline and alcohol. The metal is cleaned of rust, degreased with alcohol. Wooden surfaces are wiped with a damp cloth and dried.

When gluing Plexiglas, a small gap is left between the edges, which is filled with an adhesive composition, and then firmly pressed against each other. To get a clean seam, use a syringe with a sharp needle. The setting time depends on the composition used.

The gluing of Plexiglas on metal, wood must be carried out according to the manufacturer's instructions: method of application, holding time. Adhesives leave marks when dry. To protect surfaces from contamination, it is recommended to cover them with adhesive tape or tape.

Alternative methods

If necessary, you can perform gluing without resorting to purchased products and without making the composition at home.

The vinegar

Acetic acid is a strong acid that dissolves polymers. With its help, you can make minor repairs to Plexiglas items. The resulting seam is not durable. The connection will not withstand mechanical stresses: cracks will appear at the bends.

Acid

In addition to vinegar essence, formic acid in a concentration of more than 10% can be used to bond small parts. The quality of the seam will depend on the composition%.

Precautionary measures

Plexiglas glues contain solvents, acids, dichloroethane. These are chemically active substances that are toxic to humans. Dichloroethane is particularly dangerous, inhaling its vapors can cause general intoxication of the body and burn the larynx.

When working with adhesives, it is necessary to provide ventilation of the room, protection of eyes, respiratory tract and skin of hands. These rules can be neglected if only a small amount of glue is used.