How can you check the pressure switch of a washing machine with your own hands?

There is a washing machine in almost every household, and therefore it is quite difficult to imagine everyday life without such equipment. Owners of washing machines are often faced with the fact that the device stops working during washing. Most often, this problem appears due to a malfunction of the level switch, which is often called the pressure switch. Therefore, each owner of such equipment should know how to check the pressure switch of a washing machine.

Design and principle of operation of the device

Before starting the verification of a part, it is recommended to familiarize yourself with its design features and the principle of operation. A pressure switch is a part that is responsible for controlling the volume of water in the washing system. Different modes of operation of washing equipment require different amounts of water.Therefore, when switching, a level switch is used to check the amount of liquid in the tank.

The part is made of high quality plastic and has a rounded shape. It connects to the electrical wiring and the pressure sensing hose. Inside there is a switch with a thin membrane. When the system is filled with water, pressurized air flows through the pipe, causing the switch to close. After that, the system will stop picking up new fluid.

Malfunction symptoms

Sometimes it is quite difficult to determine the malfunction of the product, especially for people who do not understand the technology. It is recommended that you familiarize yourself with the common symptoms that indicate a malfunction of the pressure switch.

Stops collecting water in the tank

People who own their own washing machine are often faced with the fact that the liquid stops accumulating in the tank. There are several reasons for this problem:

- Problems with the valve responsible for the water supply. Liquid enters the system under tap pressure. The supply is opened using a special built-in valve, which begins to work after a signal from the control module. If it is defective, the liquid will not start to flow.

- Control module failure. Due to a malfunction of this part, no signal comes to the valve and it does not start drawing water.

- Breakage of the blocker. He is responsible for locking the hatch door. If the blocker malfunctions, the machine will not start working.

However, the most common cause is considered to be a malfunction of the pressure switch.If this product does not work, the machine will not be able to gauge and will not begin to fill the tank.

Repeated repeated cycles of watering and draining

Modern washing machines are equipped with an automatic liquid intake system. Not only valves, but also a level switch are responsible for the flow of water. All of these parts work with special commands from the control unit.

Failure of any of the listed parts leads to the system not being filled with the required amount of fluid.

The control unit perceives this as non-compliance with the command, and therefore it gives a signal again for a sip of water. This leads to the fact that the supply and drain cycles are repeated several times. Repeating cycles can significantly increase wash time.

Reduced quality of rinsing and washing

Sometimes, after using the washing machine for a long time, the rinsing and washing performance of the laundry gradually deteriorates. Many attribute this to the use of unsuitable powders. However, there are other reasons why things are starting to get worse.

A common cause of poor wash performance is a level switch failure. Due to the breakdown of this part, the washer cannot determine the amount of water in the tank, and because of this, it often does not fill completely. This leads to the fact that the collected liquid is not enough to properly wash and rinse the washed items.

Remains of water after the end of the wash

Sometimes it happens that after the end of the work, water remains inside the drum. This can happen due to the fact that the pressure switch has failed and has ceased to work normally.If it is not working properly, the control unit of the device will not receive a signal to clean the tank. This will prevent the pumps from starting to pump out excess water.

However, there are other reasons for this problem:

- Clogged pump filter. Reservoir fluid clogging sometimes occurs due to a clogged filter. It will need to be cleaned for the drain to start working.

- Blockage inside nozzle. During the emptying process, the waste liquid passes through the pipe. Experts advise you to clean it once a month so that it does not clog.

Consequences of ignoring the problem

A breakdown of the pressure switch leads to serious consequences, which should be known in advance. If the broken part is not replaced in time, the following problems will appear:

- No water is drawn. When the level switch is broken, the liquid stops accumulating. In this case, the heating element may ignite, which will further damage the heating element. Therefore, before starting the wash, be sure to check that the tank is not empty.

- Worst pumps of washed items. Sometimes, due to a component malfunction, the fluid stops flowing normally. Because of this, push-ups are much worse.

- Reservoir overflow. Sometimes, due to a breakdown of a part, a lot of water is pumped into the tank, which is why it overflows.

How to check the sensor

To make sure the sensor is working properly, you need to check it. There are several useful guidelines to help you check the health of a part.

Where is

Before proceeding with disassembly, you must understand the location of the product. Many washer owners mistakenly believe that the part is located inside the drum, but this is not the case.Most manufacturers install a level switch on the top of the drain box, which is installed near the side wall. This arrangement is considered very convenient, as it simplifies the removal of the product from the structure.

However, on some models the sensor can be installed in other locations. For example, in modern models of Samsung or Ariston washers, the part is installed on the right near the front wall. In Bosch machines, the relay is placed in the central part of the left side wall.

How to disassemble

It is quite easy to disassemble the pressure switch yourself. However, despite this, you need to familiarize yourself with how to do it correctly. The dismantling process is carried out in several sequential stages:

- Removing the top cover.To get rid of it, you will need to unscrew the two bolts that are on the back wall. Then the top cover is gently pushed back and removed.

- Part detachment. The relay is connected to wires leading to the control unit and a hose. Before removing the product, you must carefully disconnect the wiring with the hose.

- Dismantling the pressure switch. It is connected to the wall with fixing bolts, which must be unscrewed.

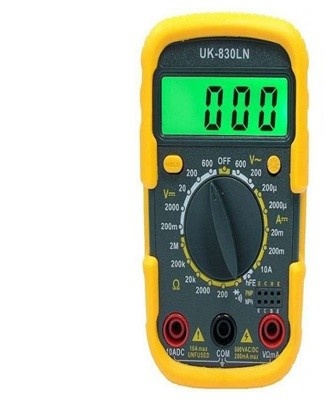

Checking with a multimeter

There are various methods for checking the performance of the device, but most often they use a multimeter for this.

Before proceeding with the test, it is necessary to carefully study the electrical circuit of the device and pre-configure the tester.

It is preset in resistance mode, after which the probes are connected to the contacts of the removed part. After connecting the probes, the values on the tester display should change. If the numbers have not changed, then the relay is faulty and it will need to be completely replaced with a new one.

DIY manual adjustment

If the breakdown turns out to be minor, you don't need to buy a new part, just manually adjust the old one. When setting up, respect the following recommendations:

- It is necessary to determine the optimal amount of water for the washing machine. For each model, there is an optimal volume of liquid that is needed to run the programs. Therefore, it is necessary to know in advance how much water should be collected in the tank for washing and rinsing things.

- Make the setting. There are adjustable screws on the surface of the product, which are adjusted according to the required amount of liquid.

How to replace

In case of more serious breakdowns, you will have to deal with the replacement of the broken product. However, a new pressure switch must be purchased before replacing it. To do this, you will need to take a broken product with you to the store and buy the exact same one.

Replacing a part is carried out in several sequential steps:

- Disassembly of the old relay. All wiring and hoses are disconnected to recover the broken part. This must be done very carefully so as not to accidentally damage anything. Then the fixing bolts are unscrewed with which the body is screwed.

- Installation of a new relay. The structure is bolted in place of the old one. Then a hose is attached to it with a clamp and the electrical wiring is connected.

Expert tips and tricks

To check the pressure switch, you should familiarize yourself with the following recommendations:

- before checking, the part must be removed from the structure of the washer;

- if an LG or Indesit machine is installed, you will need to remove the rear and front covers before removing the relay;

- during the inspection, a visual inspection of the structure is carried out to identify surface damage;

- if the exterior of the structure is intact, its performance is checked with a multimeter.

Rules of operation

To prevent the pressure switch from breaking, it is necessary to use washing equipment correctly. Several operating rules must be observed when using the machine:

- The machine should not be used when empty. Before you start washing, fill the drum at least halfway. If empty, the pressure switch will quickly break.

- Wash off with lukewarm water. Its temperature should not exceed forty-five degrees.

- Regularly clean the drain. In order for the water to drain well from the tank, it is necessary to clean the drain pipe once a month.

Conclusion

Each washer has a pressure switch, which is responsible for controlling the amount of water in the system. Sometimes a part breaks down and needs to be replaced. However, before that, you need to understand the recommendations for checking and replacing parts.