How to disassemble and repair a mixer with your own hands

Using a blender makes it possible to prepare a large number of dishes. Improper operation, external damage or third-party factors may damage the equipment. The repair functions of the mixer depend on the type of malfunction and the design of the device.

Content

- 1 Device and principle of operation

- 2 Supplement for food processor

- 3 Replacement or contacting the master

- 4 Mechanical damage

- 5 Features of the repair of manual models

- 6 What parts can fail

- 7 How to replace the clutch in desktop models

- 8 How to assemble after repair

- 9 Features of disassembly from different manufacturers

- 10 Rules of operation

Device and principle of operation

All mixers are divided into several categories, which differ from each other in design and how they are used, as well as in different accessories and features. To efficiently and correctly carry out repairs, you need to understand the design features.

Stationary

Stationary varieties outwardly resemble small food processors and are bowls with spinning knives inside. As a rule, the knives are installed at the bottom of the bowl. The device is a desktop device and does not need to be supported during operation. This blender model is capable of grinding a large portion of food at a time.

The main disadvantage of stationary devices is the need to allocate a lot of storage space. In addition, some models do not chop vegetables well and crush them into crumbs or leave pieces that are too large. In terms of repair, stationary equipment is much easier to dismantle and repair than submersible equipment.

Manual (submersible)

Hand blenders are designed as a long handle with a cutting tip. The accessory is lowered into a container with products, the device is turned on and held until the end of the grinding process. Due to their compact size, submersible devices do not require a lot of storage space in the kitchen. The ability to change attachments significantly expands the cooking list.

A negative feature of submersible structures is the need to constantly hold them in your hand and grab the start button.

This creates discomfort in the event of prolonged cooking. In addition, the device is not suitable for stirring a large part of the food.

Supplement for food processor

The mixer, which is an integral part of the combine, is in many ways similar to the stationary model. The device is built into the food processor and has many functions. If it is necessary to carry out repairs, it may be necessary to partially disassemble the combine.

Knife replacement

In case of significant damage to the knife, it must be replaced. For most models of mixers, the knife is easy to buy because they are sold as separate spare parts.

How to get out

After buying a new knife, you must first remove the old one and replace it. The process involves the following actions:

- When disassembling the appliance, first unplug the blender and remove the bowl.

- To avoid injury from a sharp blade, take a clean towel and unscrew the cutter from the motor shaft. Since the threaded connection is not standard, the knife must be unscrewed by turning it to the left.

- If the knife is secured in the bowl with nuts, wrenches or pliers should be used to remove the part.

How to disassemble the bowl

There are models of devices in which, in order to install a new knife, you will first need to disassemble the bowl. As a rule, it is enough to remove it from the central support. It is important not to forget to replace the oil seal with a new one.

If the bowl is not separable

In cases where the design features of the mixer do not allow dismantling the bowl, the only way to solve the problem is to replace the bowl with the knife. You need to choose a suitable size bowl and fix it in the right position.

Speed regulator

On many mixers there is a frequent breakdown of the speed regulator.Due to incorrect operation, the speed may change during operation or be significantly reduced.

Withdrawal from a party

In stationary versions, there is often a problem with the control of the switch due to the presence of a switch-on lock without a bowl. To remove the regulator from the case, you will need to unsolder it and check the condition of the internal components.

Alarm

Dialing the cruise control helps to find an open in an electrical circuit or a short circuit, which contributes to effective diagnosis and elimination of the problem. For continuity, a special multimeter is used. It is permitted to ring only de-energized circuits to prevent injury and damage to equipment. The procedure is carried out according to the following instructions:

- Attach the probes to the connectors on the multimeter.

- Numbering mode is activated on the device, after which the display should show a unit.

- Check that the multimeter is working correctly by connecting the probe contacts. If the device is working properly, it beeps.

- The multimeter probes are applied to the contacts of the variable speed drive. If there is no fault, the buzzer beeps and the screen displays a value close to zero.

Replacement or contacting the master

It is possible to replace a component with your own hands if you follow the instructions. In the absence of confidence in the correct replacement, it is better to contact a specialized center. Professional help will be more expensive, but it will help you quickly solve the problem that has arisen.

If the device has stopped

When the blender stops working, you need to carry out diagnostics to understand the reasons for the malfunction. In most situations, the problem can be eliminated without repair or replacement of components.

If there's a buzz

A slight hum after starting the blender means that the motor is working properly, but the device cannot start spinning the knife. In this situation, you must remove the bowl and use your fingers or a small screwdriver to press the button that blocks the start of the mechanism.

If after that the device rotates the knife in normal mode, the fault has been identified.

If it doesn't work even with the lock unlocked

Starting problems, even with the interlock disabled, indicate a malfunction in the motor winding. With this problem, there is a high probability that one or more windings have burned out, as a result of which the motor has failed. broken and must be replaced. Often the cost of a new motor is comparable to the purchase of a new mixer, so in many situations it is not profitable to replace it.

If there is no sign of life

Situations in which the mixer does not respond to switching on may indicate various malfunctions. To determine the specific cause of the malfunction, you will need to run diagnostics.

Checking the output voltage

First, you need to make sure the electrical outlet is in good working order. To do this, just connect any other device. If it works normally, the reason is not a fault in the socket and you need to continue with the diagnosis.

Checking the cord

The next step in the check is to inspect the electrical cord. In practice, it is often frayed or damaged from the inside. For diagnostics, you need to disassemble the body of the mixer and remove the cord, which is fixed inside on a special block with screws or welds. You can check the integrity of the cord with a voltmeter. The resistance level should be close to zero.In the absence of a voltmeter, it is allowed to take a new cord, replace the old one and connect to the network. If the problem persists, the problem is not with the cord.

Ringing fuse

If there is a fuse in the mixer, it must also be checked. The fuse is removed from the socket, and if it fails, the wire inside the body will be broken. It is difficult to repair a component, so it is better to replace it if it fails. All technical characteristics are indicated on the body of the fuse, according to which you can easily select a similar part.

If a new fuse breaks instantly

A blown operating fuse immediately after connecting the mixer to the mains indicates a short circuit. The problem lies in a malfunction of the control unit or the motor. In this situation, you need to connect individual units to the network and monitor the result. An ammeter is needed to check the voltage level. If the voltage is significantly higher than the nominal voltage, the source of the problem has been identified.

Visual inspection of the circuit board

A complete diagnosis also involves the inspection of the printed circuit board. Most often, capacitors fail, and this can be seen visually by their swelling. When a resistor burns out, its surface becomes dark. During the inspection, you must ensure that the connection tracks on the board do not show breaks and delamination that occur during a short circuit. Having found such defects, you will need to replace the electronic unit.

Mechanical damage

Rough handling and accidental dropping of the mixer often cause mechanical faults.Depending on which component of the device has been damaged by external influences, an appropriate repair or replacement is carried out.

Leaking gaskets and motor bowl

Having found a leak between the body and the bowl, it will not be possible to do without repair. To restart the blender, you need:

- disassemble the bowl from the body;

- unscrew the drive spindle;

- remove the damaged gasket;

- install a new gasket in its original position.

Damage to the lid locking mechanism or attachment

If the kitchen blender is used carelessly, there is a risk of damage to the lid snap-on mechanism for stationary varieties or the attachment for hand-held models. The only solution to the problem is the purchase and installation of a new part, since the repair of the latch and the attachment is laborious and can cause injury during further use of the device. It is worth it to try to repair only the whip-shaped nozzle by removing the broken twig.

In further work, you will need to be careful not to scratch yourself on the protruding piece of wire.

Damage to the mixer body

Using a device with a damaged case is not safe, and restoring the integrity of the mixer is comparable in cost to buying a new one. In order not to waste time and effort, it is easier to immediately think about buying an electrical appliance.

leg repair

In case of significant damage, the foot of the mixer cannot be repaired, since it is monolithic and it is not possible to disassemble the structure. If the leg is metal, you can make an effort and try to straighten it. It is important to take into account that even after restoring the condition of the leg, the internal mechanisms may not return to their original place.

Gearbox repair

The weak point of the gearbox is the separation of the gears and their shafts. As a result of a strong load, the assembly heats up, the iron shaft melts the seats of the gears, and they fly off. After that, the rotation transfer to the attachment stops and the mixer stops working.

To repair the gearbox, you need to disassemble it. In most varieties, this is a standard two-piece construction, joined by internal latches. After the scan, you should inspect all the details. If the gears are not damaged and have just fallen off the trees, then to restore the performance of the device, it is enough to put them back in place and securely fasten them with superglue. If the gears break, you have to buy the same size and replace it.

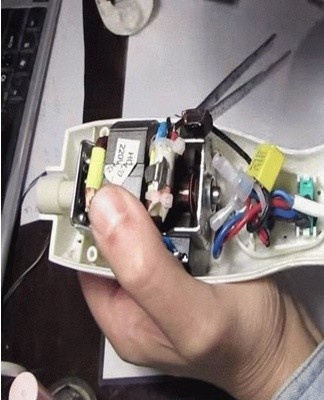

Features of the repair of manual models

Before you start repairing a manual mixer model, you should familiarize yourself with a number of features in order to avoid mistakes. Failure to observe important rules for the repair and replacement of device components can lead to more serious malfunctions.

Checking and replacing fuses

The mixer fuse, which can cause a malfunction, must be diagnosed. To check the condition, you will need to disconnect the device from the power supply, dismantle the case, remove the fuse and ring it. You can test the part using a standard multimeter. If the device indicates a malfunction, the best solution would be to purchase a new fuse.

After purchase, the component is installed in place of the previous one, and assembly is carried out in the reverse order.

Check motor contacts

You can check the status of the motor contacts by dialing the number. For this, the tester is turned on in the ohmmeter mode and is convinced of its operability.For this purpose, probes are connected. A device in operation beeps and displays a value close to zero.

To check the status of the contacts, they are alternately closed with probes. If the tester shows a value higher than the rated value, the motor contacts are malfunctioning. In the event of a breakdown, you need to replace the contacts or install a new motor.

Lubrication of HADO bearings

In the event of a malfunction of the bearings, their condition can be restored using a special grease. The substance contains a conditioner. Grease is recommended for use on bearings that wear 80% or more. After applying HADO grease, a protective coating forms on the surface, which restores the original geometry of the parts.

Rotor disassembly and lubrication

In addition to the bearings themselves, the rotor can be lubricated. The part is removed from the bearings, carefully wiped with alcohol, then grease is applied to the surface.

What parts can fail

The features of the repair of the mixer directly depend on which component has failed. Some parts can be repaired, and some need to be replaced.

Filters

Modern types of kitchen mixers have a strainer in the lid. Additionally, you can use a mesh filter by placing it in the bowl.

diode bridge

Budget models of mixers have one rotational speed, and the electric motor is powered directly from the diode bridge. A malfunction of a part leads to the fact that the engine slows down or does not start. To use the device in normal mode, you will need to carry out diagnostics and, if necessary, repair or replace the diode bridge.

Transformer

The role of a transformer in a kitchen mixer is to control the level of voltage that is transmitted to the electric motor.

Failures in the operation of the transformer lead to sudden overvoltages, short circuits and internal failure of the device.

Generator

The generator is one of the key internal components and works in conjunction with other mechanisms including the engine. It is possible to detect a malfunction of the generator only when disassembling and diagnosing the equipment.

key transistor

The key mode of transistor operation is one of the simplest and most common. Most of the time, the mixer transistor is in two states: cutoff and saturation. Failure of the transistor causes the device to not respond after power-on.

Rectifier output diodes

To check the performance of the output diodes of the rectifier, a standard numbering procedure is performed. In many types of mixers, the motor is connected via a diode. Therefore, the ability to operate the device depends on the proper functioning of the component.

Varicaps

Varicaps are semiconductor diodes. They change the capacitance in proportion to the magnitude of the applied reverse voltage.

circuit breakers

Continued use of the blender may blow the fuse. In this case, it is forbidden to use the device until it has been repaired or replaced. Otherwise, you can cause new failures.

How to replace the clutch in desktop models

The main reason for installing a new clutch is the wear of the rubber teeth. To remove the old clutch, turn it clockwise. After loosening the thread, you need to place the screwdriver under the base of the fitting to pry it up and pull it up.Then it remains to put the new part in place and fasten it securely.

How to assemble after repair

The collection characteristics of the mixer depend on the specific variety and type of construction. To properly assemble the device, you must follow the steps in reverse order.

Features of disassembly from different manufacturers

When dismantling the device, you need to take into account the design features. The technique of different manufacturers has distinctive features.

"Brown"

The main feature of Braun mixers is that during disassembly the motor is removed together with the control system. If this does not happen, you need to pull the clamp over the edge of the board.

Phillips

Philips devices have a cover on the back, under which there are 2 screws for the power cord. They hold the engine in place and prevent it from being pulled to the other side.

Bosch

To disassemble Bosch devices, it is enough to use a screwdriver. By lifting the case and removing the latches, it remains to unscrew the screws to access the mechanisms.

"Kenwood"

The process of dismantling Kenwood mixers is similar to the course of the Bosch technique. Using a screwdriver, you need to pierce the place of gluing and go through the entire case. Then, the disassembly continues from the back, by levering the regulator button in several places.

Polaris

To disassemble the devices of the manufacturer "Polaris", you need to unscrew all visible screws. After removing the mount, it is possible to separate the parts of the case and access the internal structure.

Vitek

The Vitek mixer body halves are secured with latches. The main retaining screw is located under the switch, which can be removed by prying it out with a screwdriver.

Rules of operation

When buying a blender, you should read the attached instructions for use. The basic rules are the use in accordance with its intended purpose and the loading into the bowl only of products suitable for grinding.