Description and purpose of copper paint, how to apply it correctly

The use of copper paint has many advantages. This material is considered an effective composition for decorating interior items and coloring forged products. Copper is a natural metal with a rose gold color. Copper colorants for metal products provide a natural color on various structures. This makes them more attractive to watch.

Description and peculiarities of copper paint for metal

Previously, any paint and varnish material that imitated the color of copper contained an organic solvent. This gave the substance a pungent smell and limited its use. Modern paints are made as water-soluble mixtures containing natural metallic components. Acrylates are used as binders.

These materials have the following advantages:

- Eco composition. Once dry, the material releases only moisture. In addition, the substance does not have foreign odors.

- Affordable prices. The use of a water base is inexpensive.

- Aesthetic appearance of the surface. If you want, you can give it an aged effect.

- Ease of application. Anyone can use this paint.

- Protection of the coating against humidity. Water resistance prevents corrosion processes.

- High resistance to mechanical stress and ultraviolet radiation.Thanks to this, the surface will look attractive even after many years. Subject to the conditions specified in the instructions, the lifespan of the surface is greater than 10 years.

Appointment

Copper coloring gives any metal product a solid and attractive appearance. In addition, the use of such dyes protects the coating from high humidity. This reduces the risk of corrosion.

How to choose the right solution

When choosing a solution, it is important to familiarize yourself with the characteristics of the base materials.

The most popular substances are:

- Patina is considered the most popular option for copper products. This often forms a greenish oxide film. The patina makes it possible to recreate the patina of antiquity and to change the color of the product. The zinc primer will provide additional protection.

- Semi-gloss paint - helps emphasize the appeal of metal, which is important for art forging products. When coloring inside and outside, anti-corrosion treatment will be required.

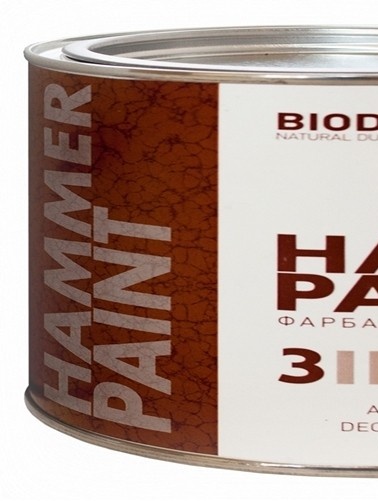

- Hammer painting - achieves an elegant structured effect. On the surface of the metal, hammered substances create the appearance of a beautiful embossing. These materials are used for the restoration of cars and motorcycles. They can be used to decorate interior and landscape elements.

Work rules

When using copper dyes, it is important to follow a number of rules and recommendations:

- To begin with, it is important to clean the metal from dirt and old coatings. For this purpose, it is permissible to use a wire brush. Coarse sandpaper is also excellent. If the old stain layer is difficult to remove, it is worth using a torch.Large amounts of rust can be removed with a special converter.

- Degrease the surface with gasoline or thinner. After that, you need to dry it well.

- Apply a coat of primer. This will protect the coating from rust and increase the adhesion of the dye to the metal. For work, a brush or a foam roller is usually used.

- After the floor has dried, it is allowed to start painting. On flat surfaces, paint should be applied by roller or spray. It is recommended to paint over the curly details with a brush.

- Dry the first layer for half an hour.

- Apply the second coat in the same way as the first.

Surface preparation

Before carrying out any work, the surface must be prepared. To do this, it is important to get rid of old stain and traces of corrosion. If this rule is violated, the material will not adhere normally. To clean the surface, it is permissible to use the following methods:

- Mechanical - a metal brush or abrasive discs are used for this. This method can only be used for materials on which rough processing is allowed. The use of personal protective equipment is also important.

- Sandblasting - special equipment is used for cleaning. At the same time, streams of sand grains are directed towards traces of corrosion, old paint and scale. This method is effective for cleaning objects even in difficult places. The disadvantage of this method is the high price of equipment.

- Chemical - special reagents are used to remove traces of corrosion and old dyes.

The next step is to apply a primer. This helps improve paint and surface adhesion, as well as protect the metal from moisture.

Dyeing

To paint a metal surface, you must do the following:

- Mix the paint with water or white spirit. In this case, you must follow the instructions on the packaging.

- Apply paint to the flat areas with a roller. Use brushes for small details.

- Dry the dye.

- Check the quality of the coloring with a brilliant jet of light. It must be directed towards the surface.

- If a richer shade is required, an additional coat of copper colorant should be applied.

Completion

At the final stage, it is worth treating the surface with varnish or wax. It is also allowed to use metal powder.

Copper paint produces a wonderful effect on metal surfaces. In this case, you should definitely strictly follow the recommendations for applying the substance. The use of personal protective equipment is also important.