Types of Craquelure wall paints and how to apply crackle effect paints

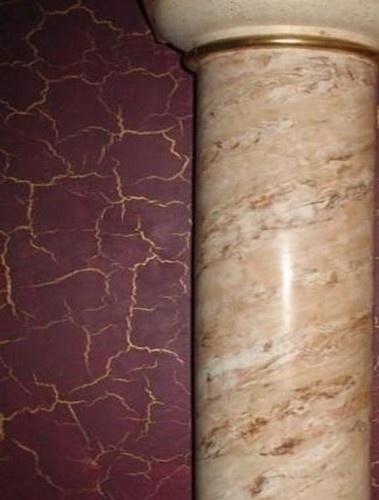

The interior, in which the effect of antiquity is achieved, is very popular. This decorative finish is used in a variety of design styles, including classic and country. Surfaces can be artificially aged using a cracked wall varnish which, after drying, forms original patterns formed by the incipient "cracks".

Purpose and composition of crackle varnishes

The main purpose of crackle varnishes is to create a decorative pattern on the walls that mimics the natural cracking of plaster. After application, this composition can be treated with acrylic paint.

Craquelure varnish can be used as an independent material and in combination with other types of finishes. This composition is used not only for the treatment of walls, but also for the decoration of interior items (cabinets, boxes, etc.).

Crackle varnish is based on printing glue (or dextrin) obtained by mixing cornstarch and water. Due to this composition, this material:

- suitable for processing various surfaces (drywall, brickwork, etc.);

- versatile (you can use different application techniques);

- moisture resistant;

- ecological;

- sustainable;

- wear resistant.

Crackle varnish, if necessary, can be made independently by mixing 850 milliliters of water and 150 grams of corn starch. This composition is able to hide minor irregularities on the surface.

What effect does

After drying, the crackle varnish makes the surface cracked. This effect is mainly used in interiors whose design requires the aging of treated materials. In this case, the cracks are not recognized after the varnish has dried.

Such "defects" can also be decorated with contrasting colors. The pattern that forms after the cracks dry out can be changed depending on the design features of the premises.

This material is also used for cutting various products. In addition, in this case, 2 different techniques are used. Some designers first treat the surface with crackles, after which they apply a decorative pattern. Others perform this operation in the reverse order: first - the main finish, which is then fixed with varnish.

Varieties of crackle and recommendations for choice

Basically, one-step or two-step crackle is used for interior decoration. Also, a special paint is used to decorate the walls, which has a similar effect. Such material simplifies and speeds up the decoration of the premises.

Monocomponent

One-component (one-step) composition is suitable for craftsmen who have never worked with similar compositions. After drying, this material forms a crack pattern through which the treated surface is visible.

It is recommended to apply this composition according to the following scheme:

- Prepare the surface.When performing this procedure, it is necessary to remember that the treated material will "see through" through the cracks after the varnish dries. Therefore, in this case, it is recommended to pre-paint the surface in a silver, metallic, golden or bronze shade. Thanks to this, the pattern of cracks on the wall will look more impressive.

- After preparation, a varnish is applied to the surface, which is treated with acrylic dyes after 40 minutes. The type of the latter is selected taking into account the design features. If shallow cracks are recreated on the surface, an acrylic varnish is recommended for crack treatment.

A day after the previous work is completed, the surface is retreated with varnish (acrylic is recommended).

Bi-component

A varnish consisting of two components is difficult to use. But at the same time, this composition allows you to recreate the original pattern of cracks on the surface. A two-component varnish is mainly applied on:

- decorative pattern;

- design;

- gold paint.

Shellac varnish is applied in several layers, after which it is covered with cracks on top. After drying, the latter is rubbed with oil paint, decorative bitumen or pastels. These works must be made with natural fabrics. Finally, another layer of shellac varnish is applied to the surface.

Microcrack

The microcrack consists of several varnishes which, after drying, form a pattern of fine cracks on the surface. Despite its two-component composition, this material is relatively easy to apply.

The surface treatment by microcracking is also carried out in several stages.First, a transparent primer is applied, after which the main composition is applied. After drying, the latter is treated with oil paint, patina or antique paste, which emphasize the pattern formed by the microcracks.

Microcrack is more often used when decorating products. This material is also used in glass processing. Like other types of cracks, this one acquires impermeability properties after drying.

Other

As noted earlier, in addition to these types of cracks, when decorating rooms, paint is used, which after drying cracks, forming an original pattern. A similar effect can be recreated using other materials.

In particular, such a pattern is obtained with the help of previously washed eggshells and brushed with warm water using a detergent. Then the film is removed from the part. At the next stage, the shell is glued to the primed surface using PVA and treated with acrylic paint.

Also, the aging effect can be achieved by using faceted varnish. This composition has a thick consistency. Due to this feature, the faceted varnish applied with a layer more than two millimeters thick, after drying, begins to crack, forming the required pattern.

What is needed for coloring

The type of materials used with the crackle is selected taking into account the peculiarities of the chosen design. This may require an acrylic undercoat and primer. A primer is used to protect the surface to be treated. And for finishing the crackle, acrylic, textured plaster, transparent fixing varnish and grout are used.

Similar requirements apply to tools that apply varnish. To work the cracks, we use sponges, brushes, cloth and rollers.If you plan to apply decorative plaster, you will need a wide spatula and sandpaper. A hair dryer is used to speed up the work.

On average, it takes up to 100 grams of crackle varnish to treat one square meter of surface.

Step-by-step working technology

The procedure for applying one-component and two-component varnishes is the same. The difference lies in the type of support on which the crack is based. It is recommended to carry out work in autumn or spring, when the walls in the room warm up to a comfortable temperature. The surface should be treated to a minimum humidity. Until the varnish is completely dry, it is impossible for drafts to appear in the room.

Surface preparation

Craquelure is applied on a pre-leveled surface that does not show any defect. Therefore, before you start decorating the walls, you need to perform the following procedures:

- Remove the old wallpaper. After removing the material, the surface must be cleaned and the irregularities must be filled.

- Remove old paint that has started to swell or crack. If the material has retained its integrity, the crack can be applied to such a surface.

- Dismantle the old concrete plaster and level the walls. The putty layer in this case should not exceed 1-2 millimeters. Otherwise, after applying the crackle, the material will begin to pull away from the wall.

- Remove dirt from the surface.

- Sand the walls. If the finish is applied over a large area, then in this case it is recommended to use a special device.

- Cover the surface with a primer. After the material has dried, the walls are repainted in a single layer.

- After the putty dries, sand the walls again with sandpaper.

Finally, the surface should be treated with a dry cloth, removing dust and residues of filler material.

Basic request

The base type is selected taking into account the features of the selected design. It is recommended to apply an acrylic paint of any appropriate shade under the crackle varnish. But the game of contrast helps to emphasize the effect of antiquity. That is, if the crackle is dark, the acrylic paint should have light shades (silver, beige, gold, etc.).

The base is applied by roller in an even coat. At this stage, it is important not to allow any smudging to form, otherwise you will need to remove the applied acrylic. After painting the wall, the material should dry for 5-6 hours.

Staining of cracks

The direction of the cracks on the wall depends on the chosen varnishing method. The decorative pattern will increase if the surface is painted vertically; on the sides - horizontally. If desired, the varnish can be applied by moving in different directions. In this case, the crack pattern will also be inhomogeneous.

The thickness of the cracks is determined by the number of layers applied: the more these there are, the deeper the first ones. You can proceed to the next working step provided that the previously applied varnish is completely dry. That is, the next layer of cracks can be applied 1-2 hours after the previous one.

Finishing

You can decorate the walls only after the varnish has completely dried. For finishing the latter, mainly acrylic paint is used, which is easier to work with.

For wall decoration after cracking, Venetian plaster is also used, which is applied with a spatula with a wide base. This material should also be applied in an arbitrary direction.The thickness of the plaster should not exceed two millimeters.

The topcoat should be applied quickly, as the crackle base begins to crack 5-10 minutes after curing. Therefore, it is recommended to carry out wall decoration works one by one, dividing the surface into small areas.

At the end of the finish, the material must dry completely. On average, this process takes up to a day. If provided for by the design of the room, after completing these stages, the cracks can be treated with a contrasting paint that will emphasize the intricate pattern.This procedure is carried out after the treated surface is completely dry.

Protective coating

To protect the coating, a special varnish is used, which is applied to the wall with a foam sponge. If acrylic paint was put on the crack, then this material can be treated with natural wax, which will improve the decorative properties of the finish.

In the event that Venetian plaster is used as a finishing coat, the surface must be prepared before applying the protective varnish. The finishing material is sanded with sandpaper, after which it is rubbed with a soft bristled cloth or brush. Then, a thin layer of protective varnish is applied with a brush. Excess material should be removed immediately.

The type of protective varnish is selected taking into account the design features. Basically, a transparent composition is used for interior decoration. You can also use polish with a metallic, silver or other sheen.

Rules of care

Despite the fact that the crack is characterized by increased wear resistance, the edges of the cracks have a fragile structure.Therefore, after the material has dried, it is necessary to avoid impacts and other mechanical effects on the finish.

Craquelure varnish is characterized by increased resistance to humidity. That is, this finish can be washed off. However, during this procedure it is forbidden to use abrasive substances or aggressive chemicals. The surface finished with cracks should be washed with a sponge dipped in a little clean water.

The secrets of the masters for quality painting

Characteristics of crackle varnish include the fact that this coating hardens quickly. Therefore, when decorating a room using such a composition, all work should be done quickly until the base dries. In particular, no more than five minutes are allocated for sealing joints.

A similar recommendation should be followed when painting walls with acrylic. But in this case, no more than a minute is allocated for joining adjacent tapes (if the work is carried out by sectors).

The drying time of finishing materials depends on the air temperature: the higher the latter, the faster the coating hardens. Apply the grout with a soft sponge. Apply this material carefully so as not to damage the fragile edges. To remove excess, vegetable oil is used, in which you need to dip a soft cloth and wipe the surface.

Overdrying varnish is one of the common mistakes that beginners face. This procedure takes an average of 30 minutes. During this time, it is necessary to form cracks on the surface using a soft sponge. It is recommended to start such work when, touching the finish, the finger sticks, but does not get dirty.

A hair dryer can be used to speed up drying.However, the device must be installed so that the air jets are inclined with respect to the treated surface.