Varieties of antistatic paints and a rating of the best, how to choose and apply

It is important to protect all coatings of industrial premises from the effects of static electricity. For this purpose, special coatings and materials are used. Special antistatic paints are considered one of the most popular and effective options. A correct composition allows to obtain excellent results. At the same time, it is important to strictly observe the technology of its application and pay attention to the preparation of the surface.

Content

- 1 Purpose and scope of antistatic paint

- 2 Additional qualities of antistatic paints

- 3 Varieties of antistatic paints

- 4 How to choose an antistatic paint: guidelines and tips

- 5 Rating of the best paints with antistatic effect

- 6 Application specificity

- 7 Application features for various surfaces

- 8 Analogs of paint materials

Purpose and scope of antistatic paint

The electrical potential created by free particles on surfaces is called static electricity. The charge is capable of accumulating to high values. In this case, at a certain moment, an electric discharge occurs, which causes sparks.

Static electricity is dangerous. Therefore, in non-residential premises it is important to protect against it. Most often, antistatic dyes are used for painting walls and floors in such situations:

- Such compositions are necessarily used in telephone exchanges, in server and computer complexes. They should also be used in television and radio studios. If an electric charge occurs in such parts, there is a risk of various breakdowns or loss of digital information. In difficult cases, the equipment may fail completely.

- Antistatic agents are used in various healthcare settings. They are needed in intensive care units, operating rooms, diagnostic centers. Such means are used in any place where there is significant equipment and patient safety is of great importance.

- Antistatic coatings are in demand in industrial buildings, electronic assembly shops and laboratories.

- Such substances must be used in all rooms where there is a risk of explosion due to the interaction of a spark with dangerous gases or combustible materials.

A distinctive feature of antistatic materials is that they do not accumulate dust and other contaminants. Therefore, these parts are very easy to clean. The materials ability to repel dust and dirt is maintained throughout the service life of the treated surfaces.

Another distinctive feature of materials is considered high environmental safety. There are no solvents in antistatic paints. In addition, they meet hygiene requirements. Such characteristics are important for hospitals, kindergartens, schools and food industries.

Quite often, antistatic dyes are used in private homes.It is also permissible to use them in premises where fire-fighting and hygienic characteristics are important.

Additional qualities of antistatic paints

Antistatic dyes have a number of unique properties:

- High coverage upon application.

- The possibility of obtaining a wear-resistant and impact-resistant coating, characterized by a high degree of elasticity. The material has anti-corrosion properties and is resistant to chemical factors.

- Creation of a film on the surface. This helps dissipate the electrostatic charge.

- Effective when applied to walls, floors and ceilings in rooms and workshops. This helps prevent the build-up of static electricity and eliminates electrical noise that affects the operation of sensitive mechanisms, devices and complex instruments.

- Possibility of application, transport and storage in a wide temperature range. It varies from -25 to +30 degrees.

- The ability to apply to different types of surfaces.

- The possibility of using indoor and outdoor structures.

- High degree of hardness and resistance. The material is able to withstand moisture. The coating is highly resistant to alkaline compounds and diluted acids. It can also be exposed to detergents and saline agents.

- Wear resistance and coating durability.

- Possibility of partial repairs if necessary.

Varieties of antistatic paints

Antistatic paints and varnishes are used to protect surfaces. In this case, the compositions are one- or two-component. The second category of products involves mixing the ingredients just before use.

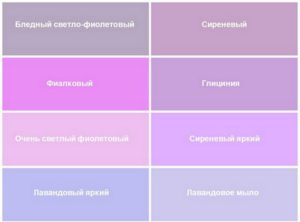

Paints and varnishes also differ in their transparency and shades. Very often, dyes are available in powder form. With such means it is permissible to process concrete, wooden or metal surfaces.In the latter case, the material additionally protects the metal from corrosion.

How to choose an antistatic paint: guidelines and tips

To select a quality material with antistatic properties, it is recommended to take into account the following characteristics:

- Hydrophobia. The coating must be highly water repellent. Thanks to this, the painted surfaces will not be saturated with moisture. In this case, it is important that the paint remains permeable to the vapor coming out of the interior.

- Resistant to temperature fluctuations. This is especially important when choosing a substance for outdoor work. Even in cold weather, the surfaces can be very hot and at night they can cool down to negative temperatures. Therefore, resistance to the difference of indicators is of great importance.

- Refractory properties. This avoids the ignition of surfaces.

- Abrasion resistance. This will help ensure a long lasting finish and avoid the need for frequent repairs.

- High degree of adhesion. Thanks to this, the material will be able to stay on the painted surface for a long time.

Rating of the best paints with antistatic effect

Quality materials that stand out for their antistatic properties are:

- "ZIPSIL 950 ASK Enamel". It is a specialized professional compound that is distinguished by its conductive and antistatic properties.

- "RADIOBUNKER 22 STATIC". This acrylic paint is highly conductive. As a result, it imparts antistatic properties to dielectric surfaces.

- Parker Chomerics CHO-SHIELD. It is a single component acrylic coating designed for a high level of electromagnetic shielding. Typically the material is used to paint plastic substrates.

Other common anti-static paint manufacturers include:

- Holland Shielding Systems BV;

- Laird Technologies;

- Bare conductor;

- MG chemicals;

- Vermason Statguard;

- YSHIELD.

Application specificity

Thoroughly mix the antistatic paint before starting work. This is done over the entire volume of the container. If necessary, it is allowed to use solvents that will help to achieve the required viscosity. These include toluene, xylene, P-4. Moreover, their share should not exceed 5% of the volume.

Antistatic dye can be applied in different ways. To do this, use a roller, brush or special devices for pneumatic or airless spraying.

Application features for various surfaces

The application of dyes to different types of surfaces has certain characteristics. To achieve uniform and quality coverage, they must be taken into account.

Surface preparation

Before applying the stain to metal surfaces, these must be thoroughly cleaned of dust, oils and dirt. It is recommended to clean rusted coatings manually or mechanically. Subsequently, they must be treated with a rust converter, which is applied in 1-2 layers. Then it is necessary to apply 2 layers of primer-enamel.

If it is necessary to paint concrete, cement or wooden surfaces, it is also important to prepare them correctly. For this purpose, the coatings are cleaned of dust, oils and dirt.

The use of the VD-AK primer is not negligible. This material is applied in 1 layer to completely get rid of dust and get an extra level of adhesion. You can also use XB-148 varnish. It is allowed to apply a primer at a temperature of at least +5 degrees.XB-148 varnish can be used at a temperature of -20 degrees. To obtain a high-quality coating, it is important to take into account the moisture parameters of the concrete surface. They should not exceed 4%.

Application technique

When applying a roller coating, do the following:

- Stir the paint well so that the deposited particles rise. Thanks to this, it will be possible to achieve a uniform consistency.

- Pour the paint from the individual cans into a general container. This achieves an even color distribution. The dye should be applied to the control area. This helps ensure optimum grip and electrical performance. If the test shows insufficient adhesion, it is recommended to use an industrial primer or putty.

- Saturate the roller with dye. It is advisable to use a fine fiber product. Then it is necessary to remove excess paint and air. To do this, it is worth rolling the roller over the tray filled with paint several times.

- Make the minimum number of passes with a roller on the surface.

The composition can also be applied with a conventional spray bottle. It is important to mix the dye well before use. It should be mixed as needed. When using a dye, the temperature should be at least +10 degrees. To achieve a high-quality result, it is worth using at least 2 layers of conductive acrylic paint.

Drying time

The painted surface should be kept at a temperature above +7 degrees until it is completely dry. Before using the second layer, it is necessary to harden the coating for at least 1-2 hours.Top coat can be applied after 48-72 hours or after last coat of stain has cured.

Chemical precautions

It is necessary to paint surfaces in well-ventilated areas or to wear a suitable respirator. It is imperative to protect your eyes with chemical goggles. Gloves should be worn on your hands. Compliance with storage conditions is not negligible. Antistatic paints should be stored in a dark place at a temperature not exceeding +25 degrees. Higher settings cause lumps to appear. This is due to the adhesion of the powder particles.

Analogs of paint materials

As an alternative to antistatic paints, you should use special linoleums. They are highly antistatic and help to withstand static loads. In addition, such a coating has thermal and sound insulation properties.

Antistatic paints are very popular. They provide excellent performance and help manage static electricity. At the same time, it is important to use these funds correctly.