How to make a ladder with your own hands, manufacturing instructions and drawings

The stepladder is considered an essential device for every home, which facilitates many types of renovation work. The folding ladder is mainly made of metal or wood. Moreover, despite the apparent complexity, you can make a stepladder with your own hands. However, this will require not only to prepare the necessary tools, but also to select a suitable drawing.

Purpose of structure

A stepladder is a folding ladder of small size and weight used primarily for renovation work. Also, this design is used for cleaning the ceiling and other hard-to-reach places. The general purpose of the ladder can be summarized as follows: these ladders are used in cases where a stable and high support is required.

Such designs have two features - the presence of a folding mechanism and low weight, which facilitates the transportation of the product. Also, there should be a wide platform at the top of the ladder..

To increase safety, anti-slip pads are applied to the feet of the stairs. Thanks to this, the ladder can be installed on any surface, including smooth.

What you need to make a homemade stepladder

The type of tools and materials is selected taking into account the features of the selected design. For wooden ladders, it is recommended to take strong bars that can withstand the weight of a person for a long time. And for a metal ladder you need a welding machine. In addition, in both cases, it is recommended to purchase the appropriate glue and rubber sheet, which, at the end of the work, will have to be fixed on the stairs, the upper platform and the legs to create a surface non-slip.

For wood

For the manufacture of a wooden ladder, it is recommended to use wood from:

- Oak;

- larch;

- pines;

- ate;

- aspen;

- birch;

- cedar;

- lime tree.

To make a wooden ladder, you need to prepare:

- wood drills;

- saw (jigsaw);

- medium grit sandpaper;

- screwdriver;

- hammer;

- self-tapping screws.

Also, for a wooden staircase, 2 chains and 4 semicircular brackets are needed, from which the clips will be made.

For metal

For a metal stepladder, you need:

- buckles;

- Bulgarian;

- Welding machine;

- edge;

- hardware fasteners;

- drill with drill bits for metal.

For the manufacture of metal stepladders, it is recommended to purchase aluminum profiles and pipes. This material is not susceptible to corrosion, lightweight and has increased stress resistance.

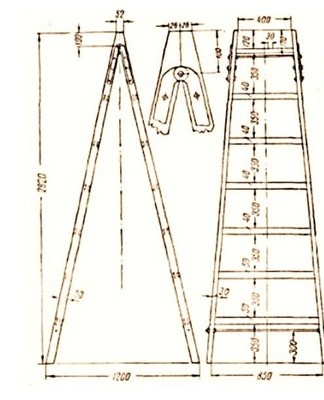

Drawings and dimensions

Without blueprints, you can only create a regular, non-folding stand. If you need a full-fledged stepladder, you can not do without a schematic drawing. When making a ladder, you can focus on the following dimensions:

- height - 70-150 centimeters;

- the difference in length between the first and the last step is 30 centimeters;

- the distance between each step is 250-330 millimeters;

- number of steps - 4-6;

- step width - 15-25 centimeters.

It is recommended to mount the bottom step at a distance of 25-35 centimeters from the floor. If necessary, the specified dimensions can be changed depending on the tasks that the stepladder has to solve.

Telescopic

Telescopic ladders come in the form of ladders with several sliding sections. These are fixed by means of hooks or other locks. These folding ladders are very tall.

Universal

The universal stepladder is divided into 2 types: telescopic and classic. However, in this case, the folding structure has steps on one side only. That is to say, this ladder can be used as an ordinary ladder.

Classic

Classic stepladders have steps on both sides and are completed with a folding mechanism. In the design of such stairs, a retainer is necessarily provided.

Stepladder chair

A step chair is a compact staircase with small legs and 2-3 steps. Such structures are designed primarily for apartments with low ceilings. The step chair is inconvenient because the ladder cannot be folded.

Manufacturing steps

The procedure for making a ladder differs significantly depending on the materials and type of design chosen. However, despite the above, there are several stages of creating this product, which can be applied in any case.

Preparatory work

At this stage, all the details of the future stepladder are being prepared. That is, you will need to cut the metal or wood into pieces in accordance with the selected drawing. All materials must be deburred. In addition, the tree must be prescribed with an antiseptic to prevent future rot.

Assembly

The general algorithm for assembling a stepladder from prepared parts is as follows:

- Steps are inserted into the side bands with drilled rack slots. If wood is used to make the stairs, each tip is pre-treated with wood glue.

- Starting from the terminal part, each tip is further reinforced with fasteners. In particular, on a wooden staircase, for this, nails are driven into the side strips or self-tapping screws are screwed.

- If boards are used instead of bars, each step is fixed by means of metal corners.

- Under each step, holes are drilled for the pins, through which the bowstrings are mounted. This tie increases the overall structural strength and increases the life of the ladder.

After two working areas (or one working and one persistent) have been assembled in the described manner, the two parts of the structure are connected from above by means of hinges with hinges or brackets. At the end, in the center or below, a chain is mounted on the ladder.

Finishing

At the final stage of making a folding ladder you will need:

- Sand all construction details with emery paper. If we are talking about a metal product, then you need to clean the edge and the attachment points of the individual elements of the ladder.

- Treat the product with an antiseptic and varnish. For metal structures, this step can be skipped.

At the end, it is also recommended to fix a non-slip material on the steps and feet.

Manufacturing Instructions

As noted, the procedure for making a ladder directly depends on the type of material selected.

Made of metal

To create a metal folding ladder, you will need:

- Cut a metal profile with a section of 20x40 millimeters into 4 equal segments, from which support posts will be made in the future.

- Drill at equal distance on the sides of the guide holes for fixing the steps.

- Cut appropriate length treads from the metal.

- Attach the guides like a wigwam with metal hinges.

- Fasten the steps to the rails using the bolts.To increase the strength of the structure, it is recommended to weld each part to the supporting legs. At this stage, it is very important to maintain the level of the steps.

At the end of the process, you also need to fix the constraints, as mentioned earlier.

In wood

To make a simple folding ladder, you need to prepare bars of the following sizes:

- 2 meters - 4 (for support);

- 59 centimeters - 2;

- 50 and 50.4 centimeters - one at a time;

- 45.5 centimeters - 1;

- 41 centimeters - 3.

You also need to prepare 2 fasteners with hinges. After that, you need to do the following:

- Mark the 2 support posts at a distance of 40 centimeters. The bottom step should be fixed at a distance of 10 centimeters from the floor.

- According to the markings, cut the grooves on the support posts.

- Cut thorns from the edges of the bars to use as steps.

- Insert the tips of the steps into the cut grooves and secure the pieces with screws or nails.

- The remaining two supports are interconnected by slats, which are attached in the form of the letter Z (two slats are installed horizontally, and the third is at an angle to the first).

- Connect the two supporting structures using metal locks with hinges or another mechanism that allows you to fold and unfold the ladder.

At the end of the work, it is recommended to attach rubber pads to the legs, and to treat the entire structure with an antiseptic and varnish (paint).

Tips & Tricks

When making a ladder, it is recommended to put a wide platform on top, using 2 boards for this. This step can be made removable. In this case, you need to cut grooves on the upper platform and fix bolts or other suitable elements on the brackets.

To simplify work and increase safety, 2 longer support legs should be cut. It is recommended to attach metal hooks to the side faces, on which you can hang the working tool. In addition, you need to install a mechanism on the ladder that will not allow the structure to open spontaneously. To do this, it is enough to hang a hook on one support, and a metal plate with a corresponding hole on the other.