Instructions for use of Poxipol glue and technical characteristics of the product

Compared to other epoxy adhesives, Poxipol provides stronger adhesion. In addition, due to a number of components that make up the product, it is able to hold even wet materials together. Gluing is carried out using the "cold welding" method. That is, after the procedure, a material remains at the junction, the strength of which is comparable to steel.

Content

- 1 Description and characteristics

- 2 Appointment

- 3 Composition and specifications

- 4 Kinds

- 5 How to use correctly

- 6 Common uses

- 6.1 Repair of aluminum bodies and radiators of cars, motorcycles

- 6.2 boat hull restoration

- 6.3 Bonding of gutter pipes, drainage channels

- 6.4 Reinforcement of the seams of an old vehicle

- 6.5 kitchen knife handle repair

- 6.6 Restoration of household appliances

- 6.7 Install hinges on furniture

- 6.8 Placement of the sink on the counter

- 6.9 Restoration

- 6.10 Fixing garden tool cuttings

- 6.11 Repair of wooden and metal windows and doors

- 6.12 Fixing hooks, pegs

- 6.13 Restoration of water tanks

- 6.14 Seal a sink or bathtub

- 6.15 Sealing various gaps in the bathroom, shower

- 6.16 Repair of garden furniture, sculptures, monuments

- 6.17 Restoration of threads on various objects

- 6.18 Fixing of stone blocks, additional fixing of tiles

- 7 Advantages and disadvantages

- 8 User tips and tricks

Description and characteristics

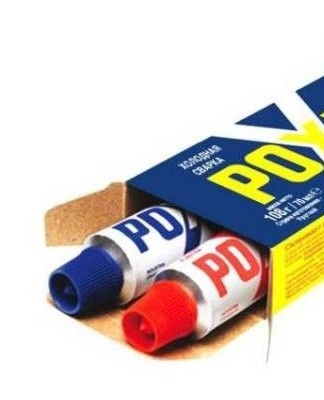

Poxipol is a two-component adhesive produced in two tubes.The first contains epoxy resin and the second contains trimethylamine hardener. The latter is necessary so that the main component dries quickly. Poxipol differs in that when stored in tubes, the characteristics of the product do not change for decades. The characteristics of this glue are as follows:

- increased grip;

- the volume of glue does not change after drying (you can apply any amount);

- the length of the complete drying period depends on the ambient temperature;

- the glue is used for application on horizontal and vertical surfaces.

Once the joints have hardened, they can be sanded, sanded or threaded in this area. The characteristics of the glue do not change under such an influence. To harden, you do not need to press the joints. The glue dries completely in 24 hours, provided there is no vibration.

Appointment

Poxipol has a wide range of applications. This adhesive is used to bond a variety of materials including:

- glass;

- metal;

- TREE;

- rubber;

- concrete.

Epoxy resin is able to bond smooth materials with a fine porous structure.

Ceramic

Despite the absence of toxic components in Poxipol, it is not recommended to use this glue to repair ceramic dishes used for serving food.

Metal

Poxipol is able to glue any metal products, provided that there are no last traces of rust on the surface.

TREE

Poxipol is used for the restoration of household furniture, doors, jambs and other wooden objects.

Concrete

This adhesive is used to repair stucco and other interior decor items that are attached to concrete surfaces.

Plastic

Poxipol is able to glue various plastic products, including those that are in constant contact with water.

Glass

Unlike other adhesives, Poxipol is able to firmly bond two glasses, regardless of the configuration of the edges of the materials.

Rubber

Poxipol is used to repair inflatable boats, car tires and other items made from this material.

Composition and specifications

Poxipol bi-component glue contains:

- an epoxy resin;

- trimethylamine;

- modifiers;

- polymercaptan and other components.

These components have the following characteristics:

- bond strength of 993 Newtons;

- cut-off voltage of 2.2 megapascals;

- average degree of fixation at breakage (glue is not used to fix parts exposed to vibrations);

- high hardening speed (no more than an hour);

- low material consumption;

- medium resistance to acids.

The glue does not contain solvents. Therefore, Poxipol has no toxic effect on living organisms. This composition tolerates a temperature increase up to +120 degrees and frosts. After drying, Poxipol does not leave streaks or streaks.

Kinds

Poxipol is available in two types. Depending on the type of adhesive, the field of application of this product varies.

Usual

The regular formulation comes in a blue box. The tubes contain a plastic-like mass designed to remove defects on the metal. The color of the material is gray-brown or white.

Transparent

The product comes in a red box. This composition has a less dense consistency. Unlike the previous one, transparent glue has dielectric properties. That is, this type of Poxipol can be used to connect current-carrying parts.

How to use correctly

According to the instructions, before applying the glue, the surface must be cleaned, removing dust, dirt and grease. For the latter, a soap or alcohol solution is used. After that, the surface is dried. It is recommended to treat metal parts with fine sandpaper. This will increase the resistance of the joint. After preparing the surface, you can start mixing the glue. To do this, squeeze the required amount of epoxy resin and add the hardener from a second tube in the same volume.

Then, with the spatula included in the kit, it is necessary to mix the two components until smooth.

The resulting glue should be lubricated on one of the surfaces. Further, the parts are strongly pressed against each other and held in this position for up to three minutes. If necessary, you can correct the position of the fragments. This should be done within 5-10 minutes. The repaired product can be used 24 hours after the restoration.

Common uses

Poxipol glue is used both in everyday life and for the repair of automotive components. This product is also used to remove surface defects from various products and to seal seams.

Repair of aluminum bodies and radiators of cars, motorcycles

Poxipol is suitable for minor repairs of automotive components. It concerns the elimination of small holes in the body, the gluing of fragments that have fallen out of the parts. When repairing cars, it is recommended to first remove dirt, as well as engine oil and rust, and then carry out restoration.

boat hull restoration

Poxipol is not suitable for quick boat repairs.This is especially true in cases where it became necessary to seal the hole in the rubber. When repairing a boat by cold welding, additional fragments of the same material from which the boat is made will be needed to eliminate defects. The adhesive is not able to seal the holes.

Bonding of gutter pipes, drainage channels

Due to the fact that the glue contains components that can withstand constant contact with moisture, using the method of cold welding, you can eliminate defects in water and drainage pipes, as well as connect these parts together to each other. It is recommended to use Poxipol with plastic products.

Reinforcement of the seams of an old vehicle

Poxipol is used as a temporary solution to reinforce joints in old car parts. To strengthen the fastening, it is recommended to solder automotive components.

kitchen knife handle repair

The properties described above expand the scope of application of Poxipol. Glue is capable of bonding wood and metal together, provided the surfaces are properly prepared.

Restoration of household appliances

As for household appliances, cold welding is used to eliminate defects on the surface of drain pipes and to seal defects on the body of appliances.

Install hinges on furniture

As with kitchen knife repairs, the ability of glue to bond different materials also applies to furniture. Poxipol in this case strengthens the fixation created by screws or self-tapping screws.

Placement of the sink on the counter

In this case, Poxipol ensures that the sink is firmly attached to the base. Sanitary ware, even after several years of regular use, remains firmly attached to the worktop.

Restoration

Poxipol demonstrates high efficiency in restoration work. The cold welding method helps repair damaged stucco, glue decorative stones to concrete, and eliminate deep defects in home furniture.

Fixing garden tool cuttings

This type of application of the cold welding method greatly improves the adhesion of cuttings to the metal parts of gardening tools. The only drawback of this method of fastening is that these elements periodically experience vibration loads, which negatively affects the strength of the connection.

Repair of wooden and metal windows and doors

In this case, cold welding is used to eliminate pronounced defects: fixing handles or hinges, fixing glass, etc.

Fixing hooks, pegs

Poxipol is used to strengthen the fixing of hooks and dowels in the wall.

Restoration of water tanks

Poxipol adheres effectively to plastic and metal tanks in which water is stored. In the latter case, before starting restoration work, it is necessary to remove traces of rust from the surface.

Seal a sink or bathtub

Cold welding can be used to join broken pieces of a ceramic sink or to repair deep flaws in the bathroom.

Sealing various gaps in the bathroom, shower

Due to epoxy being moisture resistant, Poxipol can replace traditional sealants used in bathrooms.

Repair of garden furniture, sculptures, monuments

Poxipol components are able to connect different materials together.And the epoxy resin, in combination with additional ingredients that make up this product, is resistant to temperature extremes, direct sunlight and freezing. Therefore, the glue is suitable for the restoration of products that are constantly exposed to the open air.

Restoration of threads on various objects

As stated above, Poxipol can be sanded and otherwise treated after curing. That is, glue can be applied to the places where the thread was previously, and after drying, cut a new one.

Fixing of stone blocks, additional fixing of tiles

Poxipol is recommended for small repairs. If epoxy is used to bond heavy objects such as stone or tile, this product is used in addition to other adhesives.

Advantages and disadvantages

Among the advantages of Poxipol, users highlight the following:

- Versatility. The adhesive is suitable for restoring various objects and fixing various materials. But it is better to use Poxipol when working with metal, with which this product provides the most durable connection.

- Allows you to quickly restore damaged items. Poxipol eliminates the need to purchase a new crane as it provides durable adhesion to metal for a long time.

- Ease of use. To glue the damaged parts, it is enough to mix the components of two tubes, apply to the fragments and connect the latter together by pressing for 2-3 minutes.

- Several layers of glue can be applied. This feature allows you to eliminate defects after the repair is completed.

- Seamless consistency. Therefore, after application, Poxipol remains invisible from the outside.

Poxipol has a wide range of applications and is non-toxic to humans and pets.Among the disadvantages of glue are low tensile strength, inability to withstand high temperatures and vibration.

User tips and tricks

To seal the holes in the containers with water, it is recommended to knead both components to the state of plasticine and seal the problem areas with the resulting composition. Use a trowel to level the material. To increase the degree of adhesion, a small amount of metal shavings should be added to the mass when mixing.

It is recommended to glue objects with Poxipol at temperatures from +18 to +22 degrees. Under such conditions, the composition hardens faster. If the surface to be treated is shiny, the material should be wiped with sandpaper.