Purpose and technical characteristics of Macroflex foam-glue, rules of application

The characteristics of Macroflex foam glue allow the use of the glue material indoors. In the composition there are no harmful substances (freons) that negatively affect a person. The tool is actively used for finishing work outdoors. It has a fairly wide operating temperature range. The foam retains its properties at temperatures below 0°C (-5°C) and when hot (35°C).

Description and purpose

Polyurethane is the basis of a product designed for fixing expanded polystyrene panels. Using foam glue, the insulating plates are attached to the interior and exterior walls of the house. No special skills are required for installation work. A non-specialist can work with a construction tool.

Adhesive foam contains additives that increase adhesion, it is several times higher than that of conventional polyurethane foam. Scope of foam-glue from the company "Macroflex":

- glue brick blocks;

- fixing the facing slabs of stone, wood;

- fixing the plasterboards;

- glue the window sills inside and outside;

- fixing thermal insulation materials to the facade, to the foundation.

Foam glue is a new product.It has been specially designed for bonding polystyrene and foam panels. Previously, agents containing cementitious binders were used for this purpose. Spray polyurethane foam is used for bonding different materials:

- cardboard;

- plywood;

- GVL;

- chipboard;

- drywall;

When using construction foam, work efficiency is increased. The operation of the product does not require additional equipment, water or energy consumption. There is no dirt or dust on the jobsite.

Features

A professional construction product is made in cylinders. You need a gun to apply it. The volume of the working mass in the cylinder is 850 ml, the weight is 0.99 kg. The foam glue hardens completely 2 hours after application.

| Operating temperature range | Value (°C) |

| Minimum | -5 |

| Maximum | 30 |

The product has good properties:

- thermal insulation;

- soundproof.

| Setting | Sense |

| Sound absorption index | 60dB |

| Density characteristic | 20 kg/m³ |

| Curing pressure | <10 kPa |

| Expansion rate | 40% |

| Mataining time | 25 minutes |

| Shear Strength Index | 50kPa |

| Maximum seam width | 5cm |

General application rules

The surfaces to be bonded are cleaned before applying the foam adhesive. Remove dust, bitumen, grease, dirt. They work only with dry aerated concrete blocks.

Other materials may have a wet surface. Do not apply glue to them if they are covered in ice or frost.

Ultraviolet radiation affects the properties of the glue, therefore, after hardening, it is covered with a protective layer, a layer is applied on top:

- gypsum;

- paints;

- sealant.

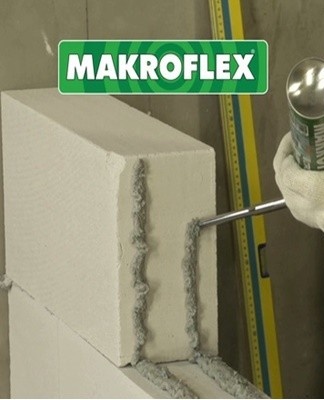

Masonry

"Macroflex" glue-foam is used to connect partition blocks. The product is not intended for load-bearing walls. Masonry is made in blocks of the correct shape and the same size. Dimension deviations must not exceed 1 mm. Do not use foam if the blocks are hollow. The base of the first row is leveled. It should be flat, strictly horizontal. Checked using a building level. Glue-foam is applied to the ends of the block (vertical, horizontal) in strips, departing from the edge by 3-5 cm. It is necessary to remove the unsuccessfully placed element within a minute.

During work, 3 minutes are taken as a reference point, this is the time during which several operations must be carried out:

- apply glue to all surfaces of the block;

- install it in place;

- easily hit the block from above to align it horizontally;

- check the horizontal level.

A wall folded with Macroflex foam adhesive can be plastered after 2 hours.

Gypsum panels

First prepare the surface of the wall (ceiling). Remove remnants of previous finishes, wallpaper, paint. Prime if the surface quickly absorbs moisture, then proceed to the main work:

- place the panel on a flat surface;

- step back from the horizontal edge 5 cm;

- press the first strip of Macroflex foam-glue, bringing it parallel to the edge;

- apply the following strips in 15 cm increments, respecting the parallelism;

- place the last strip 5 cm from the edge.

For fast and high-quality application of glue foam, it is worth buying a specialized (professional) model of a gun. When installing gypsum board, you need:

- apply glue;

- install the panel in 3 minutes;

- press the panel against the main surface, adjusting its position;

- hold for 5 minutes until the foam holds the materials together.

After 2 hours you can start the next stage of work.

window sills

Clean the surface of the window opening. Dirt and oil stains affect adhesion. You can remove them with white spirit. Squeeze the glue foam onto the prepared window sill. Apply it in parallel strips. For a solid fixation, 2-3 extruded strips are enough.

After applying the glue, reinstall the window sill. Align using a spirit level, press down. Do not remove the load within 60 minutes.

Stairs

When attaching the steps to wooden struts, the glue strips are applied parallel to the edge. For a narrow step, 2 spacers are enough. The wide requires 3, 2 on the edges, one in the middle. When applying glue, a standard distance of 10-15 cm is maintained between the strips. In 3 minutes the step is put in place, leveled, pressed. So that it does not rise, they put a load of at least 10 kg on it. They remove it after 60 minutes.

How to calculate consumption

When gluing gypsum boards, the number of cylinders is determined by calculating their total area. The content of one bottle is sufficient for 12 m². When buying foam for walls-floors, the dimensions of the blocks are taken into account. One bottle is enough for 10 m² of masonry, if the block size is 25 * 60 cm.

Using a high-quality gun, the contents of the cylinder are used as efficiently as possible. The consistency of the foam affects consumption, the denser it is, the more money is spent. A flow rate of 125 ml/m² is considered normal.

Advantages and disadvantages

The advantage is that when using glue foam from the company "Macroflex", expensive spray installations are not required. It is easy to apply using an applicator gun. Up to 25 kg of cement is replaced with one cylinder, an area of 12 m² is treated with its contents.

Feedback from non-professional buyers on the use of Macroflex foam glue is positive:

- minimum consumption;

- sticks quickly;

- expands a little;

- extruded polystyrene foam can be glued;

- perfectly glues XPS panels;

- firmly glue the penoplex.

One drawback is noted - the high price. Benefits that construction professionals confirm:

- there are no thermal bridges, thermal insulation is 100%;

- strong fixation;

- high adhesion;

- moisture, mold do not affect the characteristics of the adhesive composition.

Additional tips and tricks

The optimum temperature of the working mass inside the cylinder is 23°C. To achieve this, it is recommended to keep it at 22-25°C for about 12 hours before starting work. Use the product as follows:

- shake the ball 20 times;

- remove the protective cover;

- attach the gun.

During these operations, keep the cylinder upside down. Do the main work (apply glue), hold it upside down. The foam output speed can be adjusted as standard using the screw on the gun and the trigger. Shake the container regularly during work.

To prevent the foam from hardening, observe the following gun rules:

- do not remove it while there is foam in the container;

- when the glue runs out, quickly disconnect the empty bottle and replace it with a new one;

- after completion of work, clean the device with a special liquid (Premium Cleaner);

- Remove hardened mass mechanically.

It is recommended to store the glue cylinders for a maximum of 15 months, observing a storage temperature of 5 to 25 ° C. In this case, place them strictly vertically, the valve should look up. When transporting the product, wrap it in a cloth. Transport in the trunk. Observe safety precautions when working. Do not smoke or light a fire nearby. A supply of fresh air must be provided in the room. Protect skin of hands with gloves, eyes with goggles. Do not inhale the vapors.

Consumers appreciated the benefit of the versatile formulation. Materials of different textures are glued with glue-foam. All Macroflex products are of high quality. Foam firmly holds plexiglass, cork, gypsum, glass, wood, ceramics, metal together, securely attaches trim panels to horizontal and vertical surfaces. Buying a construction tool is not difficult. It can be ordered in the online store, which can be found at outlets in the city. Glue-foam "Macroflex" is available in construction hypermarkets and in small stores specializing in the sale of insulation materials.