Varieties of adhesives for metal and how best to glue metal at home

In everyday life, a person often encounters a situation when it is necessary to securely fasten metal parts together, but welding is not at hand. In this case, metal glue, developed specifically for working with this material, comes to the rescue. What glue for metal is better to buy in a store and what is the difference between different modifications of this product, we will find out below.

Important features

Before buying an adhesive for working with metal parts, it is worth studying its key characteristics in order to understand what information from the manufacturer to pay attention to in the first place, and what data can be ignored.

Pay attention to the following:

- possible field of application;

- properties of a heat-resistant base;

- compliance with the basic requirements for all adhesives.

Scope

An important parameter that determines the versatility of the purchased product. Some compounds are suitable only for bonding iron at home, while others are also suitable for installation work at a construction site. If this is not taken into account when buying, then there is a high probability of getting into an unpleasant situation.

To note! Some formulations are able to work not only with metal parts, but also with other materials, which greatly expands the variability of their use.

Properties of a heat-resistant base

There are times when metal parts are exposed to high temperatures. In this case, ordinary waterproof glue will not work for us, since its base will quickly crumble and become unusable. For these purposes, a special heat-resistant composition is used, the operating range of which is from 300 to 1000 degrees Celsius. Remember to pay attention to this nuance, otherwise your design will crumble in a few moments.

Requirements for adhesives

Among the basic requirements for most adhesives are:

- rapid solidification of the product;

- connection reliability;

- resistance to moisture and sudden temperature changes;

- environmental friendliness of the product;

- no significant shrinkage after solidification;

- the shelf life of the substance, during which it will correspond to the properties declared by the manufacturer.

Varieties of glues for metal products

All adhesives used to securely bond metal parts together fall into two broad categories. Looking into a particular group depends on the amount of materials the glue can interact with. Thus, the products are divided into:

- two-component formulations;

- one-component formulations.

Bi-component

Products with the help of which it is possible to connect parts made of various materials, whether:

- TREE;

- metal;

- Plastic;

- concrete.

The scope of their application is quite wide, and most of the compositions are used both for household needs and in construction.

Monocomponent

Highly specialized, fast-drying adhesives used to bond specific metal parts. During its production, all the characteristics of the working surface are taken into account, which increases the strength and durability of the grip for a particular situation.

Effective options

When you visit a hardware store to buy metal glue, your eyes literally fill with variety. In such a situation, it is difficult to choose the right product, which confuses most buyers. In order not to find yourself in a similar situation, choose one of the most effective options presented below.

Epoxy

Adhesive mixtures based on resin and various fillers, among which the advantages are:

- wear resistance;

- moisture resistance;

- they easily tolerate significant temperature changes.

cold welding

The basis of the action of cold welding is the penetration of the adhesive mass into the material of the part, which, when solidified, creates an effect similar to welding. Parts connected in this way are difficult to separate from each other, and the seam itself is able to withstand ultra-high temperatures.

Double-sided tape

Special tape coated with high quality adhesive. With its help, the two halves of metal parts and parts made of different materials are connected. A structure fastened in this way has high strength, and the joint successfully transfers the impact from the outside.

Anaerobic

A separate group of metal adhesives, the work of which is based on the hardening of the adhesive only when oxygen is no longer available. Such a connection becomes completely tight, and in terms of strength it is not inferior to other types of adhesives.

To note! The working temperature of these types of glue ranges from 18 oh Up to 30 oh... Above the specified temperature range, product performance drops significantly.

Cyanoacrylate

Cyanoacrylate glue belongs to the category of universal products used for joining materials of various origins. Advantages of the mixture:

- durable stitching;

- the mass hardens rapidly;

- the seam remains stable over a long period of time.

Defaults:

- when the ambient temperature exceeds 100 O the strength of the connection is destroyed;

- not suitable for gluing parts between which there are large gaps.

Polyurethane

Polyurethane glue differs from other analogues in the amount of synthetic resins used to make the product.They represent more than 90% of the total mass of the substance, which is significantly higher than in other products of similar use. Thanks to this composition, the fastening of the parts to each other is reliable and durable.

How to use correctly

It's not enough to buy the first glue you come across and spread it on both halves of the parts. A structure glued in this way will serve you for an extremely short time. To glue things safely and without problems, remember the following rules:

- Remember to pre-prepare the surfaces to be bonded by removing dirt and grease.

- Carefully treat the surface to be bonded, applying the substance evenly over the entire surface. Missing areas will reduce the bond strength of the parts.

- Carefully read the manufacturer's instructions for use.

Static Rigid Bonding

An excellent way to quickly and firmly bond parts that are not subject to severe physical stress during operation. These include:

- household furniture;

- showcases;

- traffic signs;

- racks in warehouses.

To note! Dynamic objects under strong physical stress cannot be stuck firmly in this way.

Deformation

Suitable for working with dynamic objects, the load on which is an order of magnitude higher than usual. You can also stick static objects if they are constantly affected by sharp temperature drops.

An epoxy resin

The use of epoxy resin makes it possible to obtain:

- Creation of an elastic seam at the seam.

- Protection against destruction of the connection during temperature fluctuations.

- Accelerate the work of restoring the part, because the epoxy resin hardens quickly.

Difficult bonding cases

Experienced builders recommend paying attention to the following situations, which are classified as difficult and require further preparation:

- interconnection of parts with different coefficients of linear expansion;

- bonding of metal parts constantly exposed to moisture.

With different coefficients of linear expansion

When working with high temperature adhesives, keep in mind that different materials react differently to heat. Thus, when gluing parts made of heterogeneous materials, glue, it is advisable to mix polyurethane additives... They will make the seam more elastic and stronger.

Metals subject to moisture

Metal that has been in a humid environment for a long time begins to oxidize. This negatively affects the strength and durability of the connection. Try to treat the seams with a special water-repellent paint, otherwise the work will soon have to be redone.

Criteria for choosing a good adhesive

When choosing an adhesive, consider the following:

- Drying speed.

- The way it is applied to the work surface.

- The operating temperature range at which the substance does not lose the characteristics declared by the manufacturer.

- A variety of materials you can work with with this glue.

- Its consistency.

Review of popular brands of professional glue

For those who don't know which brand of glue is best to choose, here is an overview of the most popular brands, with a brief description of their pros and cons.

Moment Super Epoxy Metal

Brand advantages:

- allows a metal part to be bonded to surfaces made of a different material;

- well tolerates temperature fluctuations;

- affordable price.

Defaults:

- due to its versatility, it has an average adhesion quality of the pieces, compared to profile grades.

Maple-812

Semi-professional adhesive, the advantages of which include:

- application versatility;

- at low price.

Defaults:

- not recommended for gluing things that undergo periodic shape changes.

VK-20

A heat-resistant substance with the following strengths:

- ease of use;

- good adhesion properties;

- withstands temperatures up to 1000 oh.

VS-10T

Another heat-resistant compound capable of maintaining the quality of fixing parts for up to 5 hours, with constant heating up to 300 oh... Inexpensive and sold in a practical and economical packaging.

K-300-61

This substance is difficult to find in the public domain for the average layman, since glue belongs to the category of special means. Has high adhesive properties, for which it is highly valued by specialists.

Weicon VA 110

Single component adhesive that cures when exposed to pressure and moist air. It responds well to temperature extremes and has increased resistance to the effects of various chemicals on it.

Defaults:

- the price.

Solid Steel Stick Renewal

An epoxy adhesive designed for organizing the rapid repair of damaged areas, including partial or full underwater damage. Suitable to work with:

- concrete;

- metal;

- TREE;

- ceramic;

- fiberglass.

Disadvantages:

- very expensive.

Weicon RK 1500

Strong two-component adhesive suitable for a wide range of materials including glass and plastic.

Epoximaxx

Epoxy resin of various colors and consistencies, most often used to create:

- decorations;

- trimmings;

- sign.

Can be used as a waterproof varnish.

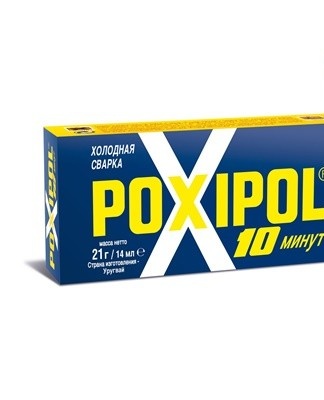

Poxipol

Cold welding of the Poxipol brand, among the advantages of which they note:

- ease of application on the working surface;

- high speed of solidification;

- Versatility.

Poxipol is non-flammable and contains no solvents.

Bison Super Glue Gel

Adhesive for installation work, renowned for its versatility and high joint strength. It is a bit expensive, but it fully justifies the money spent on its purchase.

How to glue aluminum at home

You can glue aluminum parts at home using:

- polyurethane glue;

- glue based on epoxy resin.

Expert tips and tricks

When working with metal glue, experts advise:

- thoroughly degrease the surface to be treated;

- treat the seam with a water-repellent paint;

- take your time when processing the work surface;

- don't save money on a good, high-quality glue.