Varieties and criteria for choosing a sealant for car headlights

Motorists often need to use headlight sealant. Most often it is used to glue a broken headlight glass or to completely replace a broken headlight. Before using a sealant, you should familiarize yourself with how to choose the right one.

Varieties of compositions

There are four types of compositions that are most often used by car owners.

Silicone

You can use a silicone type sealant to replace a broken car headlight. This composition is used to replace the old adhesive tape with a new one. The advantages of silicone blends include their flexibility and strength. They are also resistant to extreme temperatures and high humidity levels. However, silicone fluid loses its properties when used with antifreeze, gasoline and other machine oils.

Polyurethane

Some motorists use polyurethane compounds instead of silicone. The mixtures are resistant to high humidity and have an increased level of adhesion. Thanks to this, they can be used to glue glass in damaged headlights. However, use polyurethane sealant only for fixing stationary parts.

Anaerobic

The main characteristic of anaerobic compounds is that they do not harden in air. Anaerobic sealant hardens only after contact with bonded products. At the same time, they quickly harden, and therefore it is necessary to work very carefully with the adhesive liquid. The advantages of anaerobic sealants include their resistance to low and high temperatures, as well as different types of fuels and oils.

heat resistant

Heat-resistant adhesive mixtures that can withstand temperatures above three hundred degrees above zero are popular among motorists. Additionally, the benefits of heat-resistant sealants include their resistance to vibration and stress. These formulations are available in various forms. In stores you can find heat sealers in the form of powder, paste and even aerosol.

Choice criteria

There are several criteria to consider when choosing headlight adhesives.

Bonding reliability

Experts advise using sealants with high adhesion. Such formulations will hold reliably even if water gets into them. It is recommended to choose liquids containing plasticizers. These components make them more reliable and durable.

The amount of plasticizers should not exceed twelve percent of the total.

Anti-vibration properties

To replace car headlights, compounds with anti-vibration properties are often used. Such mixtures are considered quite good in quality, since they do not peel off even with strong vibrations. Therefore, anti-vibration compounds are most often used when gluing car headlights.

Resistance to temperature influences

Another criterion taken into account when choosing is resistance to low and high temperature indicators. When working with automotive glass and headlights, it is recommended to use a heat resistant sealant. It is the latest product that withstands extreme temperatures. Heat resistant compounds can withstand temperatures of 200 to 300 degrees above freezing.

Packing volume

When choosing a putty, you should pay attention to the packing volume in which it is sold. Basically, these adhesives are sold in containers, the volume of which is 300-320 milliliters. However, you can find the formulations in smaller packages. Some sealants are sold in 150 to 200 milliliter canisters. This amount of sealant is enough to repair or replace the headlight glass.

Ease of withdrawal

When choosing an adhesive, you need to think about the ease of its subsequent removal. Sometimes it is necessary to remove remnants of sealant that have crawled out of the headlights. It is recommended to choose funds that can be easily removed with improvised means. It is not worth choosing compounds that are removed only by mechanical means, as they can damage the surface of the car.

Transparency after application

The mastic can be transparent or translucent.Experts recommend using completely transparent liquids, since after drying they do not leave streaks on the surface, and therefore are practically invisible. However, if the product is to be applied under the headlamp, you can use translucent formulations.

Value for money

It is recommended to choose formulations with an optimal price-quality ratio. Therefore, one should not choose too expensive glues, the technical characteristics of which do not correspond to the cost.

Review of popular brands

There are several popular brands that are often used to repair car headlights.

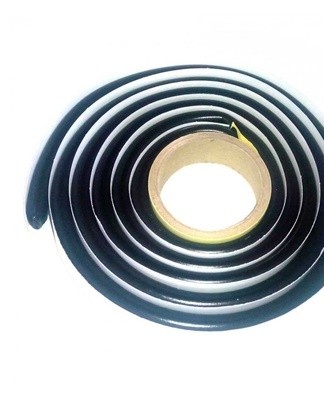

Abro WS-904

Abro is the most popular sealant manufacturer. The product is manufactured and sold in the form of a tape which is rolled up into a small roll. Abro WS-904 contains butyl alcohol, thanks to which the product dries quickly. Other benefits of sealant include:

- low price;

- resistance to temperature extremes;

- moisture resistance.

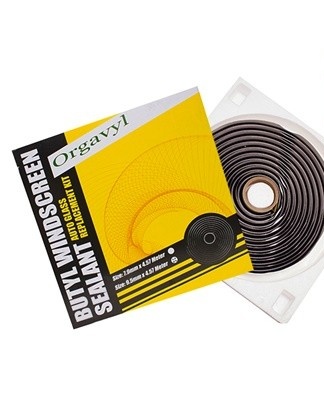

Orgavyl

This is another sealing tape often used to assemble headlights. In terms of qualities, such a tape is very similar to products produced by Abro. However, Orgavyl formulations cost an order of magnitude higher.

Dow Corning 7091

It is a one-component silicone sealant suitable for bonding metal, plastic and glass products. Characteristics of Dow Corning 7091 include ease of use, high cure rate, good strength and elasticity. This composition is appreciated by motorists due to its resistance to temperature extremes.

"Efimastica"

It is a one-component polyurethane adhesive that firmly adheres to parts and does not have an unpleasant odor. After application, "Efimastica" dries in half an hour.The product is sold in small tubes, the volume of which is 300-400 grams. It is necessary to apply such a composition to cleaned and degreased surfaces.

3M EU 590

It is an American adhesive used to bond glass and headlights to cars. The advantages of 3M PU 590 include a fast hardening speed, since the composition dries completely in twenty minutes.The putty also has disadvantages, including low resistance to high temperatures.

CompletedDeal

Another American putty, which contains components for reliable bonding of plastic or glass. DoneDeal hardens quickly after use and is resistant to sudden temperature changes. The only serious drawback of the adhesive is that after use a thin layer of sediment remains on the surface.

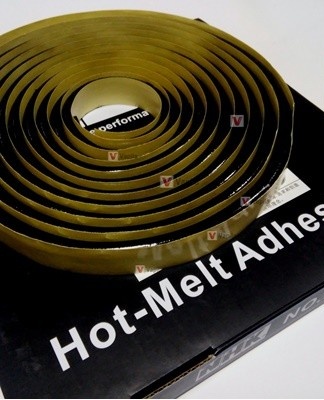

KOITO HOT Melt

People looking to buy a professional headlight sealant should check out KOITO HOT Melt. The sealant is used for reconditioning, refitting and restoring car headlights. KOITO HOT Melt cleans well on the surface. For example, at room temperature, you can peel it off with your fingers.

Permatex fluid silicone

It is a cold curing silicone compound that is used to bond glass, plastic and even wood. Permatex Fluid Silicone is also used in car headlight repairs to bond broken glass. Among the advantages of such a sealant is the fact that it penetrates into thin cracks and other hard-to-reach areas.

Manual

Before gluing car headlights with silicone, you need to understand the instructions for using these tools:

- the surface to be treated must first be degreased with alcohol;

- before gluing the glass or other part, putty is applied to the surface;

- after applying the product, the part to be bonded must be pressed firmly.

Deletion methods

There are several common putty removal methods that you should familiarize yourself with beforehand.

Warm up with a hair dryer

Using a powerful hair dryer is considered an effective method of removing silicone residue. This tool is used to warm the applied adhesive to soften it and gently wipe it off with a cloth. It is necessary to use the hair dryer carefully so as not to accidentally damage the coating and not cause mechanical damage to it.

With a knife or screwdriver

Sometimes people don't have a hair dryer handy and have to get rid of glue residue by other means. To do this, you can use a screwdriver or a kitchen knife. These tools can scratch the surface to be cleaned and should therefore be used with care. Only thick layers of putty are removed with screwdrivers and knives.

Use of solvent

People who do not want to use hair dryers, screwdrivers and knives use special solvents to remove traces of putty. Such formulations are very effective, because after using them, the silicone begins to corrode. Do not use too much solvent as it may damage the surface.

Use a body wash

If you need to get rid of the remaining adhesive from the plastic surface, you can use an auto body degreaser. However, before this, the surface is treated with a solvent in order to slightly soften the composition. If the degreaser does not work, you will need to use a mechanical removal method.

White spirit, nephras, solvent

Silicone sealant can be removed with solvent, nefras or white spirit.To remove traces of glue, dampen a cloth with detergent and then wipe the surface with it. After 2-3 minutes after that, the remnants of the product should be wiped off with a dry cloth or washed off with warm water.

Alcohols

To remove traces of glue with alcohol, proceed as follows:

- apply an alcohol solution to the surface;

- leave alcohol for 10-15 minutes;

- loosen the softened adhesive with a knife;

- wipe off the rest of the product with a damp sponge.

Common mistakes in selection and application

Several common mistakes are often made when choosing and applying sealants:

- Wrong choice of product type. Some people use inappropriate adhesives to seal.

- Application of a large amount of composition. Too much silicone is often applied to the surface. This negatively affects the adhesive properties of the composition.

- Improper surface preparation. Before using the product, the surface must be degreased.

Additional tips and tricks

There are a few additional tips to help you use the adhesive:

- it is recommended to use anti-vibration products for bonding or repairing headlight lenses;

- when applying the mastic, be very careful not to use too much product;

- it is best to remove the remnants of glue from the glass with alcohol or a degreaser.

Conclusion

Motorists are often faced with the need to use headlight sealant. Before that, it is recommended to familiarize yourself with the types of tools and the features of their use.