Which adhesive for laminate is better to choose, features of application and selection criteria

People often wonder which adhesive laminate is the best. Today there are many substances on the market that are very effective. They have different compositions and many benefits. To achieve a strong and reliable fixation, it is necessary to choose the right substance. Strict compliance with the rules of application is not negligible. As a result, it will be possible to fix the laminate well.

Content

- 1 Features of the use of laminate for wall decoration

- 2 When do you need glue to install PVC laminate?

- 3 Advantages and disadvantages of the selected laminate adhesive

- 4 Which surfaces to glue

- 5 Selection Criteria for Laminated Adhesive

- 6 Tools and materials

- 7 Rules for laying vinyl laminate on glue

- 8 The time it takes to solidify

Features of the use of laminate for wall decoration

Many people think that laminate floors are not suitable for wall decoration. Nevertheless, this coating is often used in modern design solutions. It is a high quality and durable material with high wear resistance. Therefore, people often wonder how to stick it to the wall surface.

To make a decision on the design of the premises, it is worth getting acquainted with the main advantages of this material.The advantages of laminate flooring are:

- Wear resistance. A high-quality coating is distinguished by an additional layer of protection, which helps to prevent chemical or mechanical damage to the surface.

- Respect the environment. All boards are made from shredded wood. This allows you to get the most secure material. It does not cause allergic reactions and does not lead to the evaporation of harmful elements.

- Easy to maintain. A damp cloth will help remove dust and dirt from the walls.

- Possibility of using a plaster for irregular walls. It is suitable for chipped or cracked surfaces.

- Easy to attach. Laminate flooring can be installed by yourself.

- A variety of colors and textures. This allows you to make the design universal.

- Affordable price. Thanks to the use of laminate, you can save money.

When do you need glue to install PVC laminate?

For gluing the laminate, it is allowed to use a special compound. This method is accessible and simple. To implement it, you don't need a lot of tools or serious skills. However, the method cannot be implemented in all rooms.

If there are serious defects on the surface of the wall, it is not worth fixing the laminate on it. Given the severity of the damage, it is permissible to use the following options to get out of this situation:

- make an effort to level the coating;

- use the frame installation method.

Advantages and disadvantages of the selected laminate adhesive

The advantages of using adhesives to fix laminate flooring are:

- it is possible to level the base - this method of fastening levels the difference in height;

- there is no risk of subsidence of the coating, wear of the locks and appearance of a squeak;

- the service life of the coating increases;

- most adhesives are water-repellent, which increases the resistance of materials to high humidity;

- loads on the locks are reduced - it is these parts that are considered the thinnest and weakest, they do not have moisture protection;

- the risk of water ingress at the base of the floor is reduced - this is important when laying slats on plywood or even OSB.

At the same time, the use of glue to fix the laminate has some disadvantages:

- the cost of laying increases - this is due not only to the cost of glue, but also to a significant increase in the time spent on arranging the coating;

- the productivity of construction workers decreases;

- difficulties arise when installing a laminate under insulation systems;

- many adhesives negatively perceive temperature fluctuations;

- there is no possibility of partial replacement of damaged or worn slats;

- walking on the coating is only allowed after the glue has completely dried - this takes at least a day.

Which surfaces to glue

The use of an adhesive to fix a laminate has certain characteristics. They directly depend on the coating material.

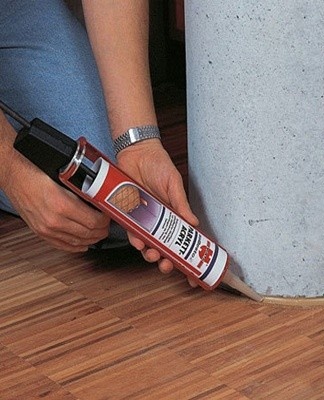

Concrete

Usually this coating has a flat surface. Therefore, it is permissible to use cement-based glue.

To increase adhesion, it is recommended to make notches on the wall, cover it with a primer and fix the plasterboard.

TREE

For lining wooden walls, it is recommended to first treat them with an antiseptic composition. Next, it's worth setting up beacons that will help achieve the most even coverage.

At a distance of 30 centimeters from the headlights, it is worth making holes in which it is recommended to place a plastic sleeve of the nail in the form of a dowel. The plasterboard should be placed on the adhesive and additionally fixed with dowel nails. Before applying the glue, the rough surface must be primed.

Brick

To fix the composition to a brick wall, glue fixing is performed. Further, the coating is made using foam or self-tapping screws. In addition, fastening on nails-dowels is allowed.

Usually the covering material is attached to polyurethane foam. The Snake coating helps control the amount of agent applied. After using it, you need to wait 2-3 minutes. As it expands, the sheet is applied to the wall and leveled.

drywall

To fix a plasterboard to the wall, you will need self-tapping screws and nails. It is also worth using an adhesive, a puncher, a construction mixer. After preparing the necessary tools and purchasing all the materials, the preparation of the rough surface is required. To do this, it is worth cleaning the wall from coating, paint or wallpaper. If there are cracks on its surface, it is recommended to strengthen and putty them. The holes are sealed with cement or plaster. It is recommended to apply a primer on top.

As it dries, it is worth preparing plasterboard. It is recommended to make holes for the sockets. To achieve a high-quality finish, you need to pay attention to the preparation of the adhesive. To do this, it is recommended to perform the following actions:

- pour the required amount of water into a clean container;

- add a small amount of dry mix and mix;

- add the rest of the powder and mix gently with a mixer.

When a homogeneous consistency is obtained, pour a small amount of PVA into the glue and mix again. Then leave the solution for 5 minutes. As a result, the additives should dissolve. This will help achieve an elastic consistency.

Selection Criteria for Laminated Adhesive

To choose a high-quality adhesive that can be used to fix the laminate, you should pay attention to the following characteristics:

- good water resistance;

- excellent viscosity and setting values;

- ease of disposal of excess;

- sustainability;

- facility security;

- ease of use.

Tomzit

This substance can be used for all types of wooden flooring, including laminate panels. This composition is characterized by high levels of moisture resistance and environmental friendliness. The substance is incredibly versatile.

Cleo Laminate

This is a tile adhesive from a French company. It is characterized by high parameters of moisture resistance, excellent adhesive properties, excellent strength. The substance is designed for the installation of slats.

To apply the substance, it is recommended to dry and degrease the surface. After that, it is allowed to start the installation immediately.

Kisel

It's German glue. The composition is loved by professional craftsmen, as it dries quickly and has high fixing strength. The substance does not contain harmful or toxic components. Therefore, it can be considered absolutely safe.

Tools and materials

Facing a vertical surface with a modern finish can be done by hand.To do this, it is recommended to stock up on the following tools:

- puncher;

- Screwdriver;

- building level;

- hammer;

- jigsaw;

- pliers;

- plumb-line;

- felt pen;

- to reign;

- various spatulas, including notched;

- a container for mixing the adhesive and a piercing accessory.

Rules for laying vinyl laminate on glue

Adhesive helps protect bits from moisture and quick wear. Therefore, it allows you to increase the service life of the coating. Laying laminate flooring is allowed in different ways. However, most often they use floating floor technology, which implies the absence of rigid attachment to the base or the walls of the room.

To install laminate flooring, you need to follow these steps:

- Attach the ends of the strips to the ends of the remaining panels. This will help you get the full line.

- Connect two rows to each other. This is done with locks.

- In the process of work, place all the boards with an offset. It is important that the joints do not match. This will make the coating more reliable and durable.

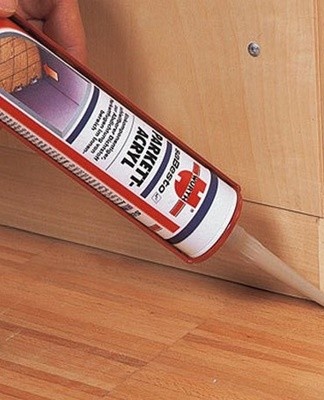

- It is imperative to treat the connection areas with the right amount of glue. However, it is not recommended to apply too much substance. Its excess will have to be removed from the front of the slats.

- It is recommended to apply the adhesive only to the upper ends. Then spread the solution over the entire length of the board.

- All connections should be placed as tightly as possible. Otherwise, there is a risk of many significant gaps.

Laying laminate floors is within everyone's reach. This job is simple, so even a layman can do it.

The time it takes to solidify

The ease of attachment of the laminate depends on the curing time of the adhesive.The appearance of a dry film on the surface of the adhesive significantly reduces the strength parameters. There is another problem with two-component substances.

Once the substance has begun to polymerize, it is not worth using glue.

The greater the interval between application and hardening, the easier it is for the master to work. In addition, when the flooring begins to be used depends on the curing period.

Today, many companies are engaged in the manufacture of adhesives for fixing laminate flooring. To achieve reliable fastening of the coating, it is worth making the right choice. For this, it is recommended to study the main characteristics of the glue.