How to make bronze paint yourself, how to dilute and apply

With the help of the bronze color of the paint, you can transform any product or object. Manufacturers of paints and varnishes produce several types of compositions that give the painted surface the appearance of bronze. The main component of any paint is bronze powder. In addition to metal powder, the composition of paint materials includes other additives. On sale you can find bronze paints for wood, metal, concrete.

Description and purpose

Bronze paint is used for decorative purposes. With the help of paint materials, which give the painted surface the appearance of bronze, you can paint products made of wood (frames, crafts), metal (gates), plaster (figurines), concrete.

The main ingredient in any bronze paint is bronze powder. The powder is obtained from copper or copper alloy. The crushed metal gives the paint a brownish-green golden color. In addition to metal powder, the composition of the paint can include resins, varnishes, polymers. You can make your own tincture from powder and drying oil.

Types of bronze paint materials:

- acrylic (for wood, interior works);

- alkyd (for metal);

- oil (for painting);

- glue (for decorative finishing);

- with hammered effect (for roughing);

- organosilicon (for metal, concrete);

- in the form of an aerosol (for spraying on a relief surface);

- anti-corrosion (for metal fences);

- heat resistant (for heated surfaces).

The main feature of bronze paint is its versatility. Painting materials can be used simultaneously for painting and protecting the surface from the adverse effects of external factors (moisture, mechanical abrasion, damage). Objects and objects painted in bronze retain their original appearance for several years. The durability of the paint depends on its composition. The most durable paint materials based on organosilicon and alkyd resins are taken into account.

Features and characteristics of the composition

Bronze paint is available in different types. The characteristics of paint materials depend on the composition. Any object or object can be painted with a dye that gives the painted surface a bronze look. In the composition of such a paint there is bound to be the smallest powder obtained from copper or a copper alloy. The use of a metal base gives the painting a number of characteristics.

How can you make yourself

Paint and varnish manufacturers produce several types of bronze paints. Such paint materials are completely ready for use and are applied to the substrate manually using a brush, roller or paint sprayer. If you wish, you can make your own bronze dye.

First you need to purchase the components that make up the composition. You can get the paint that gives the product or object the appearance of bronze from bronze powder (sold in small bags at hardware stores) and drying oil. This composition, as a rule, is used for painting wooden objects, a plastered wall.

In the manufacture of tincture, they adhere to certain rules and proportions. For ¼ of the powder, ¾ of the drying oils are taken. The components are combined and well mixed. The main thing is to pour the drying oil into the powder, and not vice versa. An alkyd varnish for wood can be used as a binder in the manufacture of a coloring substance. Usually 50 grams of bronze powder is mixed with 1 liter of drying oil or resin.

Some people even make their own heat-resistant bronze paint. This composition is used for painting stoves, fireplaces, batteries. For the manufacture of the dye, organosilicon varnish KO-185 and bronze powder are taken. When mixing, respect the proportions: 2 parts of powder and 5 parts of resin. If the composition turns out to be very thick, it is diluted with a solvent.

With the help of bronze powder and polyurethane varnish, it is possible to obtain a paint with anti-corrosion properties.This composition is used for painting a metal fence, elements of the front door. The powder is mixed with varnish in a ratio of 1: 4. The thick mixture is diluted with a solvent.

Choice criteria

Most people choose to buy ready-to-use paints and varnishes. Such bronze compositions are completely ready for use and differ in a number of unique properties. The main thing is to choose the right paint. The type of paint should match the surface to be painted. The characteristics of any composition are listed on the label.

List of existing bronze paint materials:

- acrylic dispersion (for wood, ceramics, plastic, painting objects, painting walls);

- bronze powder and drying oil (for wooden products, plaster walls);

- acrylic in cans (for painting relief products);

- organosilicon (for anti-corrosion paint of metal, for concrete, brick base);

- heat-resistant (for fireplaces, stoves, batteries);

- alkyd (for wood, metal, plaster surfaces);

- oil (for art painting).

Rules and features of the application

Bronze paint is no different from any other paint and varnish material. This is a composition that is applied to the prepared surface. For application, the same elements are used as for conventional dyes. Surface painting is done manually.

The main stages of using paint materials for bronze:

- prepare (clean, degrease, prime) the base for painting;

- wait until the surface is dry;

- mix the composition;

- add solvent or water if necessary;

- apply to the surface with a brush, roller, spray;

- you need to paint the object from top to bottom with vertical or horizontal strokes;

- wait for the first layer to dry and apply the second;

- wait until the composition is completely dry.

Thoroughly stir the finished bronze paint before use. Too thick a composition can be diluted with water or thinner. The type of thinner is indicated in the instructions, which are usually written on the label. Water, as a rule, is diluted with aqueous acrylic dispersions. To dilute varnish-based paint materials, solvents (white spirit) are used.

It is recommended to prepare the surface before painting. Do not paint wet and dirty products and objects. First, the surface must be cleaned of dirt and dust. If the product has already been painted, it is advisable to remove the remains of the old cracked coating. It is recommended to abrade a substrate that is too smooth. It is advisable to degrease the surface to be painted.

The base can be primed before applying the paint.The type of primer is selected depending on the surface. There is a primer for wood, concrete, plaster, metal, universal. The primer strengthens the surface, improves paint adhesion and reduces colorant consumption. It is possible to paint untreated products with a primer, but this is undesirable.

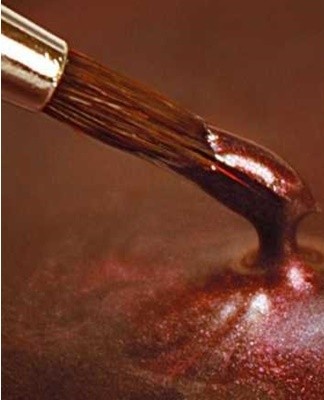

The paint is applied to a dry, clean and prepared substrate. To apply the composition, use brushes, rollers or a paint gun. The density of the mixture depends on the method of painting. For a paint sprayer, a liquid composition is made (the paint is diluted with a solvent or water). When using a brush, the mixture can be thick, like sour cream.

Bronze paint is usually applied in 1-3 coats (no more). Do not make the coating too thick, otherwise it will crack quickly. After applying a coat of paint to the surface, wait several hours for it to dry. The drying interval is indicated in the instructions. Do not apply the second coat over the wet first coat. During the drying process of paint materials, care must be taken that no water or dust gets on the surface. The painted product dries completely in 1-3 days.

If craft paint is used for painting, it is recommended to prepare a mixture before applying it to the base. First you need to mix the powder with varnish, then dilute the composition with a solvent. For painting use brushes, rollers, paint sprayer.

Solve any difficulties

Usually problems arise if you don't first prepare the surface for painting. This is especially true for items or objects with an old cracked coating. If you apply a coat of bronze over a swollen, peeling base, the paint will soon crack or peel again.

Do not paint wet products. Bronze paint may simply not stick to the substrate. It is recommended to dry the surface well before painting. It is advisable to paint objects or objects indoors or outdoors, but in dry and hot weather. It is forbidden to paint the surfaces in the rain.

Bronze paint can be applied over a painted base with acrylic, alkyd and oil. The main thing is that the old coating has an ideal surface for painting. Before using the bronze composition, it is advisable to treat the metal with fine-grained emery paper. Dyes adhere better to rough surfaces.A primer can be used to improve adhesion.