How to choose an adhesive foam for drywall, rules for use and consumption

Plasterboard is most often recommended for leveling walls and ceilings. The dry plastering method facilitates the preparation of premises for subsequent decorative finishing. An important aspect of a quality repair is how the sheets are attached to the surfaces. The use of foam glue for gluing drywall will be effective if you know the nuances of its application.

Basic Adhesive Requirements

Adhesives for plasterboard must ensure a strong bond between the tiles and the walls and the ceiling. It is necessary to have time to adjust the glued sheets relative to each other.

Main varieties: advantages and disadvantages

Adhesives can be plaster or polymer based. Gypsum adhesives offer the best connection with the panels, since it is a material close to plasterboard. Their disadvantage is rapid setting, which makes the glue to be prepared in small portions.

Polymer adhesives form a stronger bond with the surface of walls and ceilings. A long setting time makes it possible to correct defects in the coating.

Mounting glue

Assembly glue is prepared from a dry mixture on the basis of plaster with binders and adhesives just before the start of facing work. The amount of adhesive should correspond to a duty cycle of approximately 30 minutes. Assembly adhesives are used for interior work, for gluing plasterboard and insulation boards. The basis is brick, concrete, foam concrete, plastered surfaces with minor defects (potholes, deviations from level up to 2 centimeters).

The gypsum-glue mixture is packed in 30-kilogram paper bags. Water with a temperature of +5 to +30 degrees is used as a gasket. The ambient temperature should be at least +5 degrees. The shelf life of the entire package is 6 months, damaged - depending on humidity (from one day to 7 days).

For better adhesion of the mounting mixture, low-hygroscopic surfaces are pre-primed with the agent specified in the instructions. Work related to a change in the level of humidity in the room (laying self-leveling floors, leveling screed) is carried out before laying plasterboard on mounting glue. Do not add water and dry mix to the finished solution. The position of the plasterboard on the wall can be adjusted within 10 minutes after pasting.

Putty based on plaster

Plaster putty is of two types: based on wood glue or chalk. The composition is prepared immediately before gluing, in small portions. The adhesive sealant has good ductility and strength. The preparation of the adhesive consists of 2 steps. On the first, we boil wood glue: 20 grams of animal wood glue are soaked in 1 liter of water; after swelling, boil until completely dissolved and cool.Gypsum (1 kilogram) is added to a 2% adhesive solution and mixed well.

Gypsum-chalk putty contains gypsum, chalk and dextrin, water. The % ratio between the components is 70: 28: 2: 100 (respectively). Dissolve the dextrin in 1 liter of lukewarm water. Gypsum and chalk are mixed and poured into the dextrin solution.

Cretaceous putty is more plastic than glue, has a long setting period. The advantages of glue sealant are better adhesive properties.

Specialized

High-tech materials are used in the design of premises, the combination of which allows you to create projects of any complexity. The purpose of specialty adhesives is to create very strong, reliable and secure connections between materials of different classes. Specialty Adhesive Types:

- Monocomponent polyurethane. The structural composition has high adhesion and setting speed. Feature - an increase in volume when drying. The polymer is colorless and odorless. The volume of one can for household needs is 20 milliliters.

- Refractory silicate. It is used for installation and repair work on the air ducts of stoves and fireplaces, as well as their lining.

- Methacrylic. Purpose: to achieve strong connections with metal, glass, ceramics, drywall when creating design compositions.

The dosage of specialist glues in the retail trade does not exceed 1000 millilitres.

Liquid Nails

Polymer acrylic emulsion does not contain solvents, it is used for external and internal use. Glue provides moisture-resistant and heat-resistant connection of artificial products (including drywall) with smooth, porous surfaces of stone (natural and artificial), concrete, wood, metal.

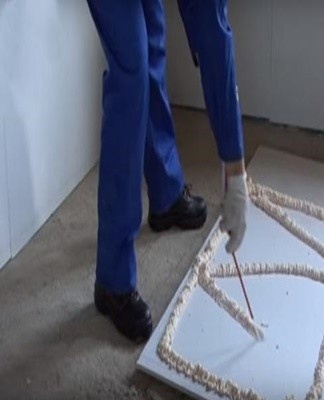

The surface of the plasterboard siding with the help of liquid nails should be flat, dry, free of dust (metal, stone treated with a degreaser). Glue is applied to drywall in dots or short strips using a gun or syringe. The curing period is 24 hours. The working temperature range is from +10 to +35 degrees. The shelf life is 1 year. Release form: container with a volume of 0.28 liters.

Polyurethane foam

Polyurethane foam contains polymers, catalysts, blowing agents and stabilizers. According to the ratio between the components, polyurethane foam is:

- summer;

- winter;

- all seasons.

Glue foam in aerosol form is pumped together with a propellant (gas-generating agent) into a metal cylinder. The mixture expelled from the container, when it interacts with the water vapor in the air, begins to expand and then polymerize (harden). Polyurethane foam is used as a sealant, sound and heat insulator, as well as a fixer for structures made of metal, PVC, wood, drywall.

How to choose the right one

The choice of an adhesive composition for drywall depends on the condition and type of surface, the surface of the coating and the temperature regime. Sealants, assembly glues are recommended for use in warm rooms with smooth walls. For liquid nails and polyurethane foam, curvature of surfaces up to 3-4 centimeters is allowed.

Work instructions

The method of leveling walls and ceilings with plasterboard depends on the linear differences in height and width. If the difference is not more than 3 centimeters, then the sheets are glued on special glue or foam.In other cases, markings are made and profiles for drywall are installed.

When installing sheets on a metal profile, a gap between the walls is formed. The air gap can be filled with polyurethane foam, which will create additional sound and heat insulation. For this, 9-12 holes are drilled in each sheet, the diameter of which coincides with the size of the barrel of the assembly gun.

A small amount of the composition is introduced through the holes under the sheet. To prevent deformation of the facing material, it is additionally reinforced from the outside with a sheet of plywood, for 10-15 minutes until the foam fully expands. On smooth walls, the sheets are glued directly to the mounting foam. Doing the job requires skill and careful preparation. Glue foam is applied in zigzag lines over the entire surface of the sheet and immediately applied to the wall. It is squeezed with effort and held in this position for 10-15 minutes.

How to correctly calculate the consumption of materials

To determine the amount of polyurethane foam for the entire surface of the coating of the wall or ceiling, the following indicators are needed:

- seam length;

- the depth of the space between the wall and the plasterboard;

- seam width.

The estimated seam path is measured on the sheet. Determine how far from the wall the plasterboard will be installed. The seam width can be chosen as desired. By multiplying three indicators, you get the expense per sheet. Dividing the result by the area of the sheet, they determine the amount needed for 1 m2 of coating.

The number of cylinders is corrected by a factor of 0.7-0.6, since the foam does not completely come out of the container.

Recommended manufacturers

The most popular among consumers are building materials from well-known German companies.

"Knauf"

The German company "KNAUF GIPS KG" was founded in 1932. The head office is located in northern Bavaria (city of Iphofen). Currently, the company is the world's leading manufacturer of building materials and components for plaster work.

Volma

Russian manufacturer working on its own base of raw materials. The headquarters are in Volgograd. The leader in the production of plasterboard, dry building mixes in Russia and the countries of the Eurasian Economic Community.

Henkel

German chemical company specializing in the production of cleaning products and adhesives. The head office is located in Düsseldorf. Subsidiaries operate in 70 countries, with a total of 340 companies.

Tips & Tricks

Before gluing drywall to walls and ceilings, the surfaces must be properly prepared. It is necessary to remove wallpaper, paint, peeling plaster. It is necessary to sweep the dust from the walls, from the ceiling, it is better to vacuum. For better adhesion of the glue to the surface, it is primed. Immediately before gluing, the surfaces are moistened with water using a spray bottle.

The choice of glue depends on the condition of the surface to be smoothed. For flat walls, choose an adhesive foam with a low coefficient of expansion, for example for expanded polystyrene. In case of significant defects, foam is used, which can fill the cracks and hollows of the wall.

It is necessary to accurately calculate the amount of glue applied to the wall or sheet so that it does not squeeze between the joints and does not complicate their subsequent sealing.It is impossible to lay electrical networks in polyurethane foam due to its high flammability. In addition to igniting, when strongly heated, it releases a large amount of toxic gases.